Influence of scan pattern and geometry on the microstructure and soft-magnetic performance of additively manufactured Fe-Si

Abstract

The influence of geometry and scan pattern on the microstructure evolution and magnetic performance of additively manufactured Fe-3Si components was investigated. To reduce eddy current losses, novel geometries were designed and built and the microstructure and properties of these samples were characterized. The laser scan pattern was shown to strongly influence both the as-built grain structure and strength of the crystallographic texture, resulting in measurable changes in the as-built magnetic performance. In thin wall samples, heat treatment resulted in an increase in the maximum relative magnetic permeability and decrease in power losses in most samples, consistent with grain growth. However, decreases in the spacing between thin walls to increase the stacking factor of the cross-section was shown to result in unwanted electrical shorting between walls and an increase in eddy current losses. Compared to simple parallel plate construction and a mesh structure, a novel cross-section design based on the Hilbert space filling curve was found to produce the lowest power losses. The mechanisms behind these results were explored using a combination of heat conduction and electromagnetic simulations, providing a route for future component and process optimization.

- Authors:

-

- Oak Ridge National Lab. (ORNL), Oak Ridge, TN (United States). Materials Science & Technology Division, and Manufacturing Demonstration Facility

- Oak Ridge National Lab. (ORNL), Oak Ridge, TN (United States). Electrical & Electronic Systems Division

- Publication Date:

- Research Org.:

- Oak Ridge National Laboratory (ORNL), Oak Ridge, TN (United States)

- Sponsoring Org.:

- USDOE Office of Energy Efficiency and Renewable Energy (EERE); USDOE Office of Electricity (OE)

- OSTI Identifier:

- 1559675

- Alternate Identifier(s):

- OSTI ID: 1877294

- Grant/Contract Number:

- AC05-00OR22725

- Resource Type:

- Accepted Manuscript

- Journal Name:

- Additive Manufacturing

- Additional Journal Information:

- Journal Volume: 29; Journal Issue: C; Journal ID: ISSN 2214-8604

- Publisher:

- Elsevier

- Country of Publication:

- United States

- Language:

- English

- Subject:

- 36 MATERIALS SCIENCE; Selective laser melting; Fe-Si; Microstructure; Soft-magnets; Magnetic characterization

Citation Formats

Plotkowski, Alex, Pries, Jason, List III, Fred, Nandwana, Peeyush, Stump, Benjamin, Carver, Keith, and Dehoff, Ryan. Influence of scan pattern and geometry on the microstructure and soft-magnetic performance of additively manufactured Fe-Si. United States: N. p., 2019.

Web. doi:10.1016/j.addma.2019.100781.

Plotkowski, Alex, Pries, Jason, List III, Fred, Nandwana, Peeyush, Stump, Benjamin, Carver, Keith, & Dehoff, Ryan. Influence of scan pattern and geometry on the microstructure and soft-magnetic performance of additively manufactured Fe-Si. United States. https://doi.org/10.1016/j.addma.2019.100781

Plotkowski, Alex, Pries, Jason, List III, Fred, Nandwana, Peeyush, Stump, Benjamin, Carver, Keith, and Dehoff, Ryan. Wed .

"Influence of scan pattern and geometry on the microstructure and soft-magnetic performance of additively manufactured Fe-Si". United States. https://doi.org/10.1016/j.addma.2019.100781. https://www.osti.gov/servlets/purl/1559675.

@article{osti_1559675,

title = {Influence of scan pattern and geometry on the microstructure and soft-magnetic performance of additively manufactured Fe-Si},

author = {Plotkowski, Alex and Pries, Jason and List III, Fred and Nandwana, Peeyush and Stump, Benjamin and Carver, Keith and Dehoff, Ryan},

abstractNote = {The influence of geometry and scan pattern on the microstructure evolution and magnetic performance of additively manufactured Fe-3Si components was investigated. To reduce eddy current losses, novel geometries were designed and built and the microstructure and properties of these samples were characterized. The laser scan pattern was shown to strongly influence both the as-built grain structure and strength of the crystallographic texture, resulting in measurable changes in the as-built magnetic performance. In thin wall samples, heat treatment resulted in an increase in the maximum relative magnetic permeability and decrease in power losses in most samples, consistent with grain growth. However, decreases in the spacing between thin walls to increase the stacking factor of the cross-section was shown to result in unwanted electrical shorting between walls and an increase in eddy current losses. Compared to simple parallel plate construction and a mesh structure, a novel cross-section design based on the Hilbert space filling curve was found to produce the lowest power losses. The mechanisms behind these results were explored using a combination of heat conduction and electromagnetic simulations, providing a route for future component and process optimization.},

doi = {10.1016/j.addma.2019.100781},

journal = {Additive Manufacturing},

number = C,

volume = 29,

place = {United States},

year = {Wed Jul 03 00:00:00 EDT 2019},

month = {Wed Jul 03 00:00:00 EDT 2019}

}

Web of Science

Figures / Tables:

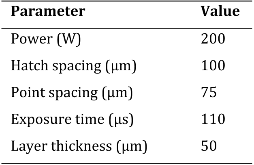

Table 1: Nominal process parameters used to build the Fe-3Si.

Table 1: Nominal process parameters used to build the Fe-3Si.

Works referenced in this record:

Bulk Combinatorial Synthesis and High Throughput Characterization for Rapid Assessment of Magnetic Materials: Application of Laser Engineered Net Shaping (LENS™)

journal, April 2016

- Geng, J.; Nlebedim, I. C.; Besser, M. F.

- JOM, Vol. 68, Issue 7

Tuning the phase stability and magnetic properties of laser additively processed Fe-30at%Ni soft magnetic alloys

journal, July 2017

- Mikler, C. V.; Chaudhary, V.; Soni, V.

- Materials Letters, Vol. 199

Laser Additive Manufacturing of Magnetic Materials

journal, January 2017

- Mikler, C. V.; Chaudhary, V.; Borkar, T.

- JOM, Vol. 69, Issue 3

Laser additive processing of Ni-Fe-V and Ni-Fe-Mo Permalloys: Microstructure and magnetic properties

journal, April 2017

- Mikler, C. V.; Chaudhary, V.; Borkar, T.

- Materials Letters, Vol. 192

Microstructure and Magnetic Properties of Fe–Ni Alloy Fabricated by Selective Laser Melting Fe/Ni Mixed Powders

journal, August 2013

- Zhang, Baicheng; Fenineche, Nour-Eddine; Liao, Hanlin

- Journal of Materials Science & Technology, Vol. 29, Issue 8

Iron and silicon-iron alloys

journal, March 1971

- Littmann, M.

- IEEE Transactions on Magnetics, Vol. 7, Issue 1

Magnetic properties and workability of 6.5% Si steel sheet

journal, July 1996

- Haiji, H.; Okada, K.; Hiratani, T.

- Journal of Magnetism and Magnetic Materials, Vol. 160

Recent researches on high silicon-iron alloys

journal, November 1981

- Narita, K.; Teshima, N.; Mori, Y.

- IEEE Transactions on Magnetics, Vol. 17, Issue 6

Influence of alloy elements on the plasticity of high-silicon iron

journal, December 1985

- Glezer, A. M.; Maleeva, I. V.; Zakharov, A. I.

- Metal Science and Heat Treatment, Vol. 27, Issue 12

Effect of nickel and manganese addition on ductility and magnetic properties of 6.5% silicon-iron alloy

journal, July 1978

- Narita, K.; Enokizono, M.

- IEEE Transactions on Magnetics, Vol. 14, Issue 4

Commercial scale production of Fe‐6.5 wt. % Si sheet and its magnetic properties

journal, November 1988

- Takada, Y.; Abe, M.; Masuda, S.

- Journal of Applied Physics, Vol. 64, Issue 10

Magnetic properties of commercially produced Fe-6.5wt% Si sheet

journal, March 1989

- Abe, M.; Takada, Y.; Murakami, T.

- Journal of Materials Engineering, Vol. 11, Issue 1

Improvement of magnetic properties of an Fe–6.5wt.% Si alloy by directional solidification

journal, May 2011

- Fu, Huadong; Zhang, Zhihao; Jiang, Yanbin

- Materials Letters, Vol. 65, Issue 9

Texture Development in High-Silicon Iron Sheet Produced by Simple Shear Deformation

journal, March 2016

- Kustas, Andrew B.; Sagapuram, Dinakar; Trumble, Kevin P.

- Metallurgical and Materials Transactions A, Vol. 47, Issue 6

Texture control during laser deposition of nickel-based superalloy

journal, September 2012

- Dinda, G. P.; Dasgupta, A. K.; Mazumder, J.

- Scripta Materialia, Vol. 67, Issue 5

Site specific control of crystallographic grain orientation through electron beam additive manufacturing

journal, November 2014

- Dehoff, R. R.; Kirka, M. M.; Sames, W. J.

- Materials Science and Technology, Vol. 31, Issue 8

Localized melt-scan strategy for site specific control of grain size and primary dendrite arm spacing in electron beam additive manufacturing

journal, November 2017

- Raghavan, Narendran; Simunovic, Srdjan; Dehoff, Ryan

- Acta Materialia, Vol. 140

Highly Anisotropic Steel Processed by Selective Laser Melting

journal, May 2013

- Niendorf, Thomas; Leuders, Stefan; Riemer, Andre

- Metallurgical and Materials Transactions B, Vol. 44, Issue 4

Relationship between laser energy input, microstructures and magnetic properties of selective laser melted Fe-6.9%wt Si soft magnets

journal, September 2018

- Garibaldi, M.; Ashcroft, I.; Hillier, N.

- Materials Characterization, Vol. 143

Calorimetric study and microstructure analysis of the order-disorder phase transformation in silicon steel built by SLM

journal, October 2017

- Lemke, J. N.; Simonelli, M.; Garibaldi, M.

- Journal of Alloys and Compounds, Vol. 722

Effect of annealing on the microstructure and magnetic properties of soft magnetic Fe-Si produced via laser additive manufacturing

journal, January 2018

- Garibaldi, M.; Ashcroft, I.; Lemke, J. N.

- Scripta Materialia, Vol. 142

Metallurgy of high-silicon steel parts produced using Selective Laser Melting

journal, May 2016

- Garibaldi, Michele; Ashcroft, Ian; Simonelli, Marco

- Acta Materialia, Vol. 110

Geometry-Induced Spatial Variation of Microstructure Evolution During Selective Electron Beam Melting of Rene-N5

journal, August 2018

- Frederick, Curtis Lee; Plotkowski, Alexander; Kirka, Michael M.

- Metallurgical and Materials Transactions A, Vol. 49, Issue 10

Analysis of solidification microstructures in Fe-Ni-Cr single-crystal welds

journal, June 1990

- Rappaz, M.; David, S. A.; Vitek, J. M.

- Metallurgical Transactions A, Vol. 21, Issue 6

In-process closed-loop control for stabilising the melt pool temperature in selective laser melting

journal, May 2019

- Renken, Volker; von Freyberg, Axel; Schünemann, Kevin

- Progress in Additive Manufacturing, Vol. 4, Issue 4

Additive manufacturing of metallic components – Process, structure and properties

journal, March 2018

- DebRoy, T.; Wei, H. L.; Zuback, J. S.

- Progress in Materials Science, Vol. 92

The metallurgy and processing science of metal additive manufacturing

journal, March 2016

- Sames, W. J.; List, F. A.; Pannala, S.

- International Materials Reviews, Vol. 61, Issue 5

Calculation of solidification-related thermophysical properties for steels

journal, April 1997

- Miettinen, Jyrki

- Metallurgical and Materials Transactions B, Vol. 28, Issue 2

Efficient additive manufacturing production of oxide- and nitride-dispersion-strengthened materials through atmospheric reactions in liquid metal deposition

journal, December 2016

- Springer, H.; Baron, C.; Szczepaniak, A.

- Materials & Design, Vol. 111

Grain structure evolution in Inconel 718 during selective electron beam melting

journal, June 2016

- Helmer, H.; Bauereiß, A.; Singer, R. F.

- Materials Science and Engineering: A, Vol. 668

Works referencing / citing this record:

Additive Manufacturing and Topology Optimization of Magnetic Materials for Electrical Machines—A Review

journal, January 2021

- Pham, Thang; Kwon, Patrick; Foster, Shanelle

- Energies, Vol. 14, Issue 2

Figures / Tables found in this record:

Search WorldCat to find libraries that may hold this journal

Search WorldCat to find libraries that may hold this journal