Influence of scan pattern and geometry on the microstructure and soft-magnetic performance of additively manufactured Fe-Si

- Oak Ridge National Lab. (ORNL), Oak Ridge, TN (United States). Materials Science & Technology Division, and Manufacturing Demonstration Facility

- Oak Ridge National Lab. (ORNL), Oak Ridge, TN (United States). Electrical & Electronic Systems Division

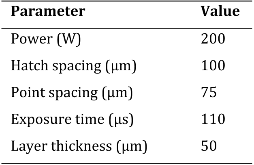

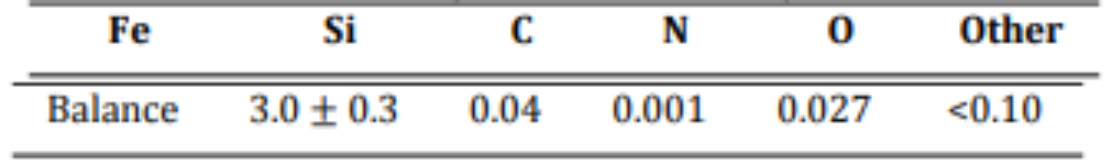

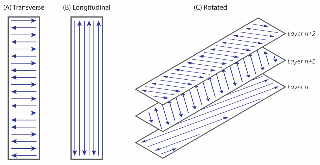

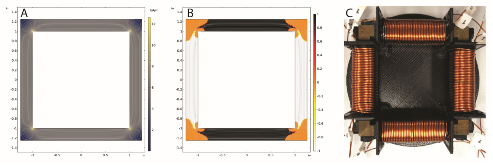

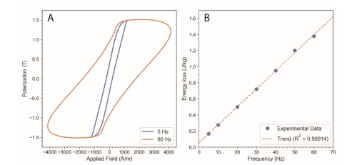

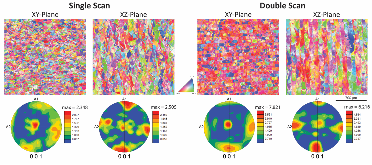

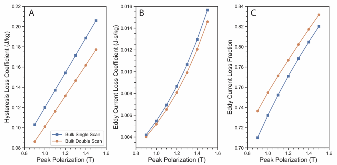

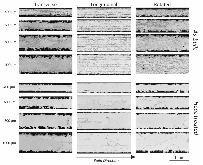

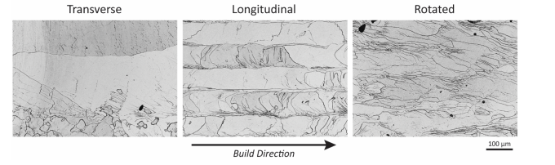

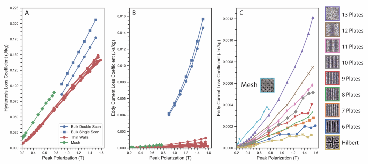

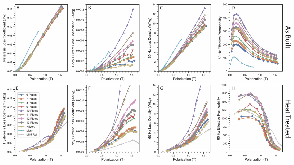

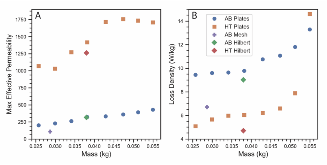

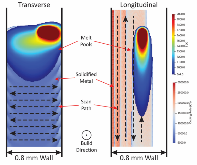

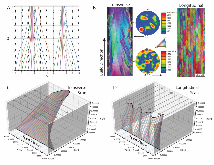

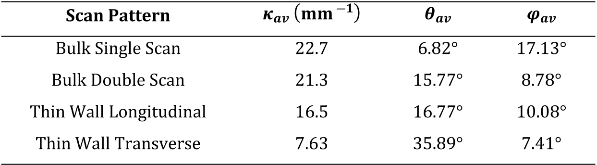

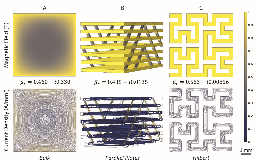

The influence of geometry and scan pattern on the microstructure evolution and magnetic performance of additively manufactured Fe-3Si components was investigated. To reduce eddy current losses, novel geometries were designed and built and the microstructure and properties of these samples were characterized. The laser scan pattern was shown to strongly influence both the as-built grain structure and strength of the crystallographic texture, resulting in measurable changes in the as-built magnetic performance. In thin wall samples, heat treatment resulted in an increase in the maximum relative magnetic permeability and decrease in power losses in most samples, consistent with grain growth. However, decreases in the spacing between thin walls to increase the stacking factor of the cross-section was shown to result in unwanted electrical shorting between walls and an increase in eddy current losses. Compared to simple parallel plate construction and a mesh structure, a novel cross-section design based on the Hilbert space filling curve was found to produce the lowest power losses. The mechanisms behind these results were explored using a combination of heat conduction and electromagnetic simulations, providing a route for future component and process optimization.

- Research Organization:

- Oak Ridge National Laboratory (ORNL), Oak Ridge, TN (United States)

- Sponsoring Organization:

- USDOE Office of Energy Efficiency and Renewable Energy (EERE); USDOE Office of Electricity (OE)

- Grant/Contract Number:

- AC05-00OR22725

- OSTI ID:

- 1559675

- Alternate ID(s):

- OSTI ID: 1877294

- Journal Information:

- Additive Manufacturing, Vol. 29, Issue C; ISSN 2214-8604

- Publisher:

- ElsevierCopyright Statement

- Country of Publication:

- United States

- Language:

- English

Web of Science

Additive Manufacturing and Topology Optimization of Magnetic Materials for Electrical Machines—A Review

|

journal | January 2021 |

Similar Records

Digital Twin Model for Advanced Manufacture of a Rotating Detonation Engine Injector

Characterization of Fe-6Si Soft Magnetic Alloy Produced by Laser-Directed Energy Deposition Additive Manufacturing