Increasing M2(dobdc) Loading in Selective Mixed-Matrix Membranes: A Rubber Toughening Approach

Abstract

Mixed-matrix membranes (MMMs) were formed by incorporating M2(dobdc) (M = Mg, Ni; dobdc4– = 2,5-dioxido-1,4-benzenedicarboxylate) metal–organic framework (MOF) nanoparticles in a series of poly(ether-imide) copolymers. Addition of the MOF nanoparticles improved the permeability of H2, N2, CH4, and CO2 relative to the pure copolymer by increasing gas solubility and, in most cases, diffusivity. More limited improvements in diffusivity were observed for the more strongly adsorbing gases. Because of such transport considerations, improvements in permeability and selectivity were most pronounced for H2/CH4 and H2/N2 separations. Incorporation of a greater ether content within the copolymers led to the formation of defect-free MMMs by physically sealing polymer–MOF interfacial defects, allowing higher MOF loadings to be achieved. For Mg2(dobdc), selective, defect-free films could be formed with loadings of up to 51 wt %. However, at these high loadings, films became weak and brittle. The mechanical properties of the composite materials were therefore quantified by tensile tests and compared to those of the neat polymers used commercially for membrane film formation. High contents of flexible ether units and small MOF nanoparticle sizes were found to be necessary to form strong and ductile MMMs, although clear trade-offs exist between transport performance, MOF loading, and mechanical properties.more »

- Authors:

-

- Univ. of California, Berkeley, CA (United States). Dept. of Chemistry; Massachusetts Inst. of Technology (MIT), Cambridge, MA (United States). Dept. of Chemical Engineering

- Univ. of California, Berkeley, CA (United States). Dept. of Chemical and Biomolecular Engineering

- Univ. of California, Berkeley, CA (United States). Dept. of Materials Science and Engineering; ShanghaiTech Univ., Shanghai (China). School of Physical Science and Technology

- Univ. of New South Wales, Sydney, NSW (Australia). School of Mechanical and Manufacturing Engineering

- National Energy Technology Lab. (NETL), Pittsburgh, PA (United States)

- Univ. of California, Berkeley, CA (United States). Dept. of Chemistry; Univ. of California, Berkeley, CA (United States). Dept. of Materials Science and Engineering

- Univ. of California, Berkeley, CA (United States). Dept. of Materials Science and Engineering; Lawrence Berkeley National Lab. (LBNL), Berkeley, CA (United States). Materials Sciences Division

- Univ. of California, Berkeley, CA (United States). Dept. of Chemistry; Univ. of California, Berkeley, CA (United States). Dept. of Chemical and Biomolecular Engineering

- Publication Date:

- Research Org.:

- National Energy Technology Laboratory (NETL), Pittsburgh, PA, Morgantown, WV (United States); Energy Frontier Research Centers (EFRC) (United States). Center for Gas Separations Relevant to Clean Energy Technologies (CGS)

- Sponsoring Org.:

- USDOE Office of Science (SC), Basic Energy Sciences (BES)

- OSTI Identifier:

- 1455423

- Grant/Contract Number:

- SC0001015; FE0004000

- Resource Type:

- Accepted Manuscript

- Journal Name:

- Chemistry of Materials

- Additional Journal Information:

- Journal Volume: 30; Journal Issue: 5; Journal ID: ISSN 0897-4756

- Publisher:

- American Chemical Society (ACS)

- Country of Publication:

- United States

- Language:

- English

- Subject:

- 36 MATERIALS SCIENCE; 37 INORGANIC, ORGANIC, PHYSICAL, AND ANALYTICAL CHEMISTRY

Citation Formats

Smith, Zachary P., Bachman, Jonathan E., Li, Tao, Gludovatz, Bernd, Kusuma, Victor A., Xu, Ting, Hopkinson, David P., Ritchie, Robert O., and Long, Jeffrey R. Increasing M2(dobdc) Loading in Selective Mixed-Matrix Membranes: A Rubber Toughening Approach. United States: N. p., 2018.

Web. doi:10.1021/acs.chemmater.7b02908.

Smith, Zachary P., Bachman, Jonathan E., Li, Tao, Gludovatz, Bernd, Kusuma, Victor A., Xu, Ting, Hopkinson, David P., Ritchie, Robert O., & Long, Jeffrey R. Increasing M2(dobdc) Loading in Selective Mixed-Matrix Membranes: A Rubber Toughening Approach. United States. https://doi.org/10.1021/acs.chemmater.7b02908

Smith, Zachary P., Bachman, Jonathan E., Li, Tao, Gludovatz, Bernd, Kusuma, Victor A., Xu, Ting, Hopkinson, David P., Ritchie, Robert O., and Long, Jeffrey R. Tue .

"Increasing M2(dobdc) Loading in Selective Mixed-Matrix Membranes: A Rubber Toughening Approach". United States. https://doi.org/10.1021/acs.chemmater.7b02908. https://www.osti.gov/servlets/purl/1455423.

@article{osti_1455423,

title = {Increasing M2(dobdc) Loading in Selective Mixed-Matrix Membranes: A Rubber Toughening Approach},

author = {Smith, Zachary P. and Bachman, Jonathan E. and Li, Tao and Gludovatz, Bernd and Kusuma, Victor A. and Xu, Ting and Hopkinson, David P. and Ritchie, Robert O. and Long, Jeffrey R.},

abstractNote = {Mixed-matrix membranes (MMMs) were formed by incorporating M2(dobdc) (M = Mg, Ni; dobdc4– = 2,5-dioxido-1,4-benzenedicarboxylate) metal–organic framework (MOF) nanoparticles in a series of poly(ether-imide) copolymers. Addition of the MOF nanoparticles improved the permeability of H2, N2, CH4, and CO2 relative to the pure copolymer by increasing gas solubility and, in most cases, diffusivity. More limited improvements in diffusivity were observed for the more strongly adsorbing gases. Because of such transport considerations, improvements in permeability and selectivity were most pronounced for H2/CH4 and H2/N2 separations. Incorporation of a greater ether content within the copolymers led to the formation of defect-free MMMs by physically sealing polymer–MOF interfacial defects, allowing higher MOF loadings to be achieved. For Mg2(dobdc), selective, defect-free films could be formed with loadings of up to 51 wt %. However, at these high loadings, films became weak and brittle. The mechanical properties of the composite materials were therefore quantified by tensile tests and compared to those of the neat polymers used commercially for membrane film formation. High contents of flexible ether units and small MOF nanoparticle sizes were found to be necessary to form strong and ductile MMMs, although clear trade-offs exist between transport performance, MOF loading, and mechanical properties. In conclusion, these trade-offs are critically examined to evaluate the current limitations and potential benefits to forming M2(dobdc) MMMs using this rubber toughening approach.},

doi = {10.1021/acs.chemmater.7b02908},

journal = {Chemistry of Materials},

number = 5,

volume = 30,

place = {United States},

year = {Tue Jan 30 00:00:00 EST 2018},

month = {Tue Jan 30 00:00:00 EST 2018}

}

Web of Science

Figures / Tables:

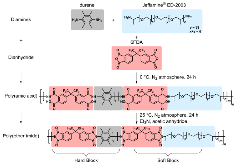

Figure 1: Synthesis of poly(ether-imide) copolymers.

Figure 1: Synthesis of poly(ether-imide) copolymers.

Works referenced in this record:

Gas Separation Membrane Materials: A Perspective

journal, September 2014

- Baker, Richard W.; Low, Bee Ting

- Macromolecules, Vol. 47, Issue 20

Natural Gas Processing with Membranes: An Overview

journal, April 2008

- Baker, Richard W.; Lokhandwala, Kaaeid

- Industrial & Engineering Chemistry Research, Vol. 47, Issue 7

The solution-diffusion model: a review

journal, November 1995

- Wijmans, J. G.; Baker, R. W.

- Journal of Membrane Science, Vol. 107, Issue 1-2

The upper bound revisited

journal, July 2008

- Robeson, Lloyd M.

- Journal of Membrane Science, Vol. 320, Issue 1-2, p. 390-400

Mixed matrix membranes (MMMs) comprising organic polymers with dispersed inorganic fillers for gas separation

journal, April 2007

- Chung, Tai-Shung; Jiang, Lan Ying; Li, Yi

- Progress in Polymer Science, Vol. 32, Issue 4, p. 483-507

Metal organic framework based mixed matrix membranes: An increasingly important field of research with a large application potential

journal, January 2013

- Zornoza, Beatriz; Tellez, Carlos; Coronas, Joaquin

- Microporous and Mesoporous Materials, Vol. 166

Mixed matrix membranes using carbon molecular sieves

journal, January 2003

- Vu, De Q.; Koros, William J.; Miller, Stephen J.

- Journal of Membrane Science, Vol. 211, Issue 2

Mixed matrix membranes using carbon molecular sieves

journal, January 2003

- Vu, De Q.; Koros, William J.; Miller, Stephen J.

- Journal of Membrane Science, Vol. 211, Issue 2

Membrane Gas Separation: A Review/State of the Art

journal, May 2009

- Bernardo, P.; Drioli, E.; Golemme, G.

- Industrial & Engineering Chemistry Research, Vol. 48, Issue 10

High performance ZIF-8/6FDA-DAM mixed matrix membrane for propylene/propane separations

journal, February 2012

- Zhang, Chen; Dai, Ying; Johnson, Justin R.

- Journal of Membrane Science, Vol. 389

Unexpected Molecular Sieving Properties of Zeolitic Imidazolate Framework-8

journal, July 2012

- Zhang, Chen; Lively, Ryan P.; Zhang, Ke

- The Journal of Physical Chemistry Letters, Vol. 3, Issue 16

In Situ Synthesis of Thin Zeolitic–Imidazolate Framework ZIF-8 Membranes Exhibiting Exceptionally High Propylene/Propane Separation

journal, July 2013

- Kwon, Hyuk Taek; Jeong, Hae-Kwon

- Journal of the American Chemical Society, Vol. 135, Issue 29

Sharp separation of C2/C3 hydrocarbon mixtures by zeolitic imidazolate framework-8 (ZIF-8) membranes synthesized in aqueous solutions

journal, January 2011

- Pan, Yichang; Lai, Zhiping

- Chemical Communications, Vol. 47, Issue 37

Comprehensive study of carbon dioxide adsorption in the metal–organic frameworks M 2 (dobdc) (M = Mg, Mn, Fe, Co, Ni, Cu, Zn)

journal, January 2014

- Queen, Wendy L.; Hudson, Matthew R.; Bloch, Eric D.

- Chem. Sci., Vol. 5, Issue 12

Selective adsorption of ethylene over ethane and propylene over propane in the metal–organic frameworks M2(dobdc) (M = Mg, Mn, Fe, Co, Ni, Zn)

journal, January 2013

- Geier, Stephen J.; Mason, Jarad A.; Bloch, Eric D.

- Chemical Science, Vol. 4, Issue 5

Dramatic Tuning of Carbon Dioxide Uptake via Metal Substitution in a Coordination Polymer with Cylindrical Pores

journal, August 2008

- Caskey, Stephen R.; Wong-Foy, Antek G.; Matzger, Adam J.

- Journal of the American Chemical Society, Vol. 130, Issue 33, p. 10870-10871

CO2/N2 separations with mixed-matrix membranes containing Mg2(dobdc) nanocrystals

journal, January 2013

- Bae, Tae-Hyun; Long, Jeffrey R.

- Energy & Environmental Science, Vol. 6, Issue 12

Enhanced ethylene separation and plasticization resistance in polymer membranes incorporating metal–organic framework nanocrystals

journal, April 2016

- Bachman, Jonathan E.; Smith, Zachary P.; Li, Tao

- Nature Materials, Vol. 15, Issue 8

Plasticization-resistant Ni 2 (dobdc)/polyimide composite membranes for the removal of CO 2 from natural gas

journal, January 2016

- Bachman, Jonathan E.; Long, Jeffrey R.

- Energy & Environmental Science, Vol. 9, Issue 6

Molecular sieving realized with ZIF-8/Matrimid® mixed-matrix membranes

journal, September 2010

- Ordoñez, Ma. Josephine C.; Balkus, Kenneth J.; Ferraris, John P.

- Journal of Membrane Science, Vol. 361, Issue 1-2, p. 28-37

Dynamic molecular interactions between polyurethane and ZIF-8 in a polymer-MOF nanocomposite: Microstructural, thermo-mechanical and viscoelastic effects

journal, August 2016

- Mahdi, E. M.; Tan, Jin-Chong

- Polymer, Vol. 97

Mixed-matrix membranes of zeolitic imidazolate framework (ZIF-8)/Matrimid nanocomposite: Thermo-mechanical stability and viscoelasticity underpinning membrane separation performance

journal, January 2016

- Mahdi, E. M.; Tan, Jin-Chong

- Journal of Membrane Science, Vol. 498

Physical aging in glassy mixed matrix membranes; tuning particle interaction for mechanically robust nanocomposite films

journal, January 2016

- Smith, Stefan J. D.; Lau, Cher Hon; Mardel, James I.

- Journal of Materials Chemistry A, Vol. 4, Issue 27

Effect of methyl substituents on permeability and permselectivity of gases in polyimides prepared from methyl-substituted phenylenediamines

journal, July 1992

- Tanaka, Kazuhiro; Okano, Masaaki; Toshino, Hiroyuki

- Journal of Polymer Science Part B: Polymer Physics, Vol. 30, Issue 8

Phase structure and adhesion in polymer blends: A criterion for rubber toughening

journal, November 1985

- Wu, Souheng

- Polymer, Vol. 26, Issue 12

Influence of Diffusivity and Sorption on Helium and Hydrogen Separations in Hydrocarbon, Silicon, and Fluorocarbon-Based Polymers

journal, April 2014

- Smith, Zachary P.; Tiwari, Rajkiran R.; Dose, Michelle E.

- Macromolecules, Vol. 47, Issue 9

The Time Lag in Diffusion

journal, January 1957

- Frisch, H. L.

- The Journal of Physical Chemistry, Vol. 61, Issue 1

Relationship between gas transport properties and fractional free volume determined from dielectric constant in polyimide films containing the hexafluoroisopropylidene group

journal, January 2007

- Miyata, Sou; Sato, Shuichi; Nagai, Kazukiyo

- Journal of Applied Polymer Science, Vol. 107, Issue 6

Preparation and gas separation properties of partially pyrolyzed membranes (PPMs) derived from copolyimides containing polyethylene oxide side chains

journal, August 2012

- Huertas, R. M.; Doherty, C. M.; Hill, A. J.

- Journal of Membrane Science, Vol. 409-410

Performance studies of mixed matrix membranes for gas separation: A review

journal, November 2010

- Aroon, M. A.; Ismail, A. F.; Matsuura, T.

- Separation and Purification Technology, Vol. 75, Issue 3

Poly(imide siloxane) and carbon nanotube mixed matrix membranes for gas separation

journal, May 2006

- Kim, Sangil; Pechar, Todd W.; Marand, Eva

- Desalination, Vol. 192, Issue 1-3

Gas solubility, diffusivity and permeability in poly(ethylene oxide)

journal, August 2004

- Lin, H.; Freeman, B. D.

- Journal of Membrane Science, Vol. 239, Issue 1

Thermal transitions in α,ω-diamino terminated poly(oxypropylene)-block-poly(oxyethylene)-block-poly(oxypropylene) aqueous solutions and their epoxy networks

journal, May 2005

- Gómez Ribelles, Jose Luis; Salmerón Sanchez, Manuel; de la Osa, Luis Torres

- Journal of Non-Crystalline Solids, Vol. 351, Issue 14-15

Fluorinated polycarbonates for gas separation applications

journal, September 1989

- Hellums, M. W.; Koros, W. J.; Husk, G. R.

- Journal of Membrane Science, Vol. 46, Issue 1

Predictive Models for Mixed-Matrix Membrane Performance: A Review

journal, March 2013

- Vinh-Thang, Hoang; Kaliaguine, Serge

- Chemical Reviews, Vol. 113, Issue 7

637. The stability of transition-metal complexes

journal, January 1953

- Irving, H.; Williams, R. J. P.

- Journal of the Chemical Society (Resumed), Vol. 0, Issue 0, p. 3192-3210

Hybrid membrane materials comprising organic polymers with rigid dispersed phases

journal, January 2004

- Moore, Theodore T.; Mahajan, Rajiv; Vu, De Q.

- AIChE Journal, Vol. 50, Issue 2

Diffusion of Gases in Polyethylene Terephthalate

journal, January 1963

- Michaels, Alan S.; Vieth, Wolf R.; Barrie, James A.

- Journal of Applied Physics, Vol. 34, Issue 1

Characterization of permeability and sorption in Matrimid/C60 mixed matrix membranes

journal, January 2003

- Chung, Tai-Shung; Chan, Sun Sun; Wang, Rong

- Journal of Membrane Science, Vol. 211, Issue 1

The effects of polymer chain rigidification, zeolite pore size and pore blockage on polyethersulfone (PES)-zeolite A mixed matrix membranes

journal, September 2005

- Li, Y.; Chung, T.; Cao, C.

- Journal of Membrane Science, Vol. 260, Issue 1-2

Basis of Permeability/Selectivity Tradeoff Relations in Polymeric Gas Separation Membranes

journal, January 1999

- Freeman, Benny D.

- Macromolecules, Vol. 32, Issue 2

Water Reaction Mechanism in Metal Organic Frameworks with Coordinatively Unsaturated Metal Ions: MOF-74

journal, November 2014

- Tan, Kui; Zuluaga, Sebastian; Gong, Qihan

- Chemistry of Materials, Vol. 26, Issue 23

Competitive Coadsorption of CO 2 with H 2 O, NH 3 , SO 2 , NO, NO 2 , N 2 , O 2 , and CH 4 in M-MOF-74 (M = Mg, Co, Ni): The Role of Hydrogen Bonding

journal, March 2015

- Tan, Kui; Zuluaga, Sebastian; Gong, Qihan

- Chemistry of Materials, Vol. 27, Issue 6

The diffusion time lag in polymer membranes containing adsorptive fillers

journal, January 1973

- Paul, D. R.; Kemp, D. R.

- Journal of Polymer Science: Polymer Symposia, Vol. 41, Issue 1

Enhanced H2 Adsorption in Isostructural Metal−Organic Frameworks with Open Metal Sites: Strong Dependence of the Binding Strength on Metal Ions

journal, November 2008

- Zhou, Wei; Wu, Hui; Yildirim, Taner

- Journal of the American Chemical Society, Vol. 130, Issue 46, p. 15268-15269

Computational and Experimental Studies on the Adsorption of CO, N 2 , and CO 2 on Mg-MOF-74

journal, June 2010

- Valenzano, L.; Civalleri, B.; Chavan, S.

- The Journal of Physical Chemistry C, Vol. 114, Issue 25

Evaluating metal–organic frameworks for natural gas storage

journal, January 2014

- Mason, Jarad A.; Veenstra, Mike; Long, Jeffrey R.

- Chemical Science, Vol. 5, Issue 1, p. 32-51

Evaluating metal–organic frameworks for post-combustion carbon dioxide capture via temperature swing adsorption

journal, January 2011

- Mason, Jarad A.; Sumida, Kenji; Herm, Zoey R.

- Energy & Environmental Science, Vol. 4, Issue 8, p. 3030-3040

CO2/CH4, CH4/H2 and CO2/CH4/H2 separations at high pressures using Mg2(dobdc)

journal, March 2012

- Herm, Zoey R.; Krishna, Rajamani; Long, Jeffrey R.

- Microporous and Mesoporous Materials, Vol. 151

Works referencing / citing this record:

High gas permselectivity in ZIF‐302/polyimide self‐consistent mixed‐matrix membrane

journal, September 2019

- Ghanem, Akram S.; Ba‐Shammakh, Mohamed; Usman, Muhammad

- Journal of Applied Polymer Science, Vol. 137, Issue 13

Performance of Mixed Matrix Membranes Containing Porous Two-Dimensional (2D) and Three-Dimensional (3D) Fillers for CO2 Separation: A Review

journal, July 2018

- Ahmadi, Mahdi; Janakiram, Saravanan; Dai, Zhongde

- Membranes, Vol. 8, Issue 3

2D molecular crystal lattices: advances in their synthesis, characterization, and application

journal, January 2019

- Solomos, Marina A.; Claire, F. James; Kempa, Thomas J.

- Journal of Materials Chemistry A, Vol. 7, Issue 41

Engineering of the Filler/Polymer Interface in Metal–Organic Framework‐Based Mixed‐Matrix Membranes to Enhance Gas Separation

journal, July 2019

- Ma, Liang; Svec, Frantisek; Lv, Yongqin

- Chemistry – An Asian Journal, Vol. 14, Issue 20

Search WorldCat to find libraries that may hold this journal

Search WorldCat to find libraries that may hold this journal