A Bi-Level Formulation And Solution Method For The Integration Of Process Design And Scheduling

- Texas A & M Univ., College Station, TX (United States); Texas A&M University

- Texas A & M Univ., College Station, TX (United States)

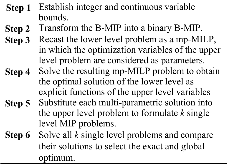

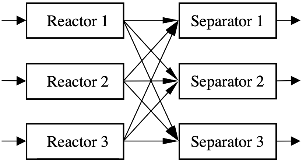

Design and operation decisions of manufacturing plants can often be expressed within a hierarchical structure, where optimal decisions at lower operating level provide constraints for the decision raking at a higher decision level. In this work, we are addressing the case of a hierarchical design and scheduling optimization problem. The integration of design and scheduling decisions can play a big role in designing economically profitable plants and improving their operational performance. This problem can be expressed as a bi-level problem, where design related decisions occur at the upper level and operational scheduling decisions at the lower level. Since discrete decisions are involved in both optimization levels, the resulting formulation typically corresponds to bi-level mixed-integer programming problems (B-MIP). The solution of B-MIP problems is very challenging, and typically requires the use of global optimization techniques, with many algorithms not able to guarantee feasibility. To overcome the challenges in solving this class of problems we propose the use of a multi-parametric based algorithm for the solution of bi-level mixed-integer linear and quadratic programming problems, capable of providing the exact and global solution. The main idea of this approach is to treat the lower scheduling problem as a multi-parametric programming problem in which the design decisions are considered as parameters. Here, the resulting parametric solutions can then be substituted into the upper level design problem, which can be solved as a set of single-level deterministic programming problems. Through the developed formulation and algorithm we are able to supply the decision makers with the exact solution of the integrated design and scheduling problem.

- Research Organization:

- RAPID Manufacturing Institute, New York, NY (United States)

- Sponsoring Organization:

- USDOE Office of Energy Efficiency and Renewable Energy (EERE), Energy Efficiency Office. Advanced Manufacturing Office; National Science Foundation

- Grant/Contract Number:

- EE0007888

- OSTI ID:

- 1642416

- Journal Information:

- Computer Aided Chemical Engineering, Journal Name: Computer Aided Chemical Engineering Vol. 47; ISSN 1570-7946

- Publisher:

- ElsevierCopyright Statement

- Country of Publication:

- United States

- Language:

- English

Similar Records

Optimal scheduling of isolated microgrid with an electric vehicle battery swapping station in multi-stakeholder scenarios: A bi-level programming approach via real-time pricing