In situ recovery of bio-based carboxylic acids

Abstract

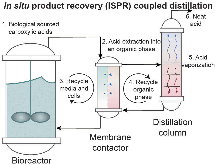

The economics of chemical and biological processes is often dominated by the expense of downstream product separations from dilute product streams. Continuous separation techniques, such as in situ product recovery (ISPR), are attractive in that they can concentrate products from a reactor and minimize solvent loss, thereby increasing purity and sustainability of the process. In bioprocesses, ISPR can have an additional advantage of increasing productivity by alleviating product inhibition on the microorganism. In this work, we developed a liquid–liquid extraction (LLE)-based ISPR system integrated with downstream distillation to selectively purify free carboxylic acids, which were selected as exemplary bioproducts due to their ability to be produced at industrially relevant titers and productivities. Equilibrium constants for the extraction of carboxylic acids into a phosphine-oxide based organic phase were experimentally determined. Complete recovery of acids from the extractant and recyclability of the organic phase were demonstrated through multiple extraction–distillation cycles. Using these data, an equilibrium model was developed to predict the acid loading in the organic phase as a function of the extraction equilibrium constant, initial aqueous acid concentration, pH, organic to aqueous volume ratio, and temperature. A distillation process model was then used to predict the energy input required to distillmore »

- Authors:

-

- National Renewable Energy Lab. (NREL), Golden, CO (United States)

- Pennsylvania State Univ., University Park, PA (United States)

- Publication Date:

- Research Org.:

- National Renewable Energy Lab. (NREL), Golden, CO (United States)

- Sponsoring Org.:

- USDOE Office of Energy Efficiency and Renewable Energy (EERE)

- OSTI Identifier:

- 1432608

- Alternate Identifier(s):

- OSTI ID: 1434342

- Report Number(s):

- NREL/JA-5100-71279

Journal ID: ISSN 1463-9262; GRCHFJ

- Grant/Contract Number:

- AC36-08GO28308

- Resource Type:

- Accepted Manuscript

- Journal Name:

- Green Chemistry

- Additional Journal Information:

- Journal Volume: 20; Journal Issue: 8; Journal ID: ISSN 1463-9262

- Publisher:

- Royal Society of Chemistry

- Country of Publication:

- United States

- Language:

- English

- Subject:

- 09 BIOMASS FUELS; liquid-liquid extraction; in situ product recovery; distillation; carboxylic acids

Citation Formats

Saboe, Patrick O., Manker, Lorenz P., Michener, William E., Peterson, Darren J., Brandner, David G., Deutch, Stephen P., Kumar, Manish, Cywar, Robin M., Beckham, Gregg T., and Karp, Eric M. In situ recovery of bio-based carboxylic acids. United States: N. p., 2018.

Web. doi:10.1039/C7GC03747C.

Saboe, Patrick O., Manker, Lorenz P., Michener, William E., Peterson, Darren J., Brandner, David G., Deutch, Stephen P., Kumar, Manish, Cywar, Robin M., Beckham, Gregg T., & Karp, Eric M. In situ recovery of bio-based carboxylic acids. United States. https://doi.org/10.1039/C7GC03747C

Saboe, Patrick O., Manker, Lorenz P., Michener, William E., Peterson, Darren J., Brandner, David G., Deutch, Stephen P., Kumar, Manish, Cywar, Robin M., Beckham, Gregg T., and Karp, Eric M. Fri .

"In situ recovery of bio-based carboxylic acids". United States. https://doi.org/10.1039/C7GC03747C. https://www.osti.gov/servlets/purl/1432608.

@article{osti_1432608,

title = {In situ recovery of bio-based carboxylic acids},

author = {Saboe, Patrick O. and Manker, Lorenz P. and Michener, William E. and Peterson, Darren J. and Brandner, David G. and Deutch, Stephen P. and Kumar, Manish and Cywar, Robin M. and Beckham, Gregg T. and Karp, Eric M.},

abstractNote = {The economics of chemical and biological processes is often dominated by the expense of downstream product separations from dilute product streams. Continuous separation techniques, such as in situ product recovery (ISPR), are attractive in that they can concentrate products from a reactor and minimize solvent loss, thereby increasing purity and sustainability of the process. In bioprocesses, ISPR can have an additional advantage of increasing productivity by alleviating product inhibition on the microorganism. In this work, we developed a liquid–liquid extraction (LLE)-based ISPR system integrated with downstream distillation to selectively purify free carboxylic acids, which were selected as exemplary bioproducts due to their ability to be produced at industrially relevant titers and productivities. Equilibrium constants for the extraction of carboxylic acids into a phosphine-oxide based organic phase were experimentally determined. Complete recovery of acids from the extractant and recyclability of the organic phase were demonstrated through multiple extraction–distillation cycles. Using these data, an equilibrium model was developed to predict the acid loading in the organic phase as a function of the extraction equilibrium constant, initial aqueous acid concentration, pH, organic to aqueous volume ratio, and temperature. A distillation process model was then used to predict the energy input required to distill neat acid from an organic phase as a function of the acid loading in the organic phase feed. The heat integrated distillation train can achieve neat recovery of acetic acid with an energy input of 2.6 MJ kg-1 of acetic acid. This LLE-based ISPR system integrated with downstream distillation has an estimated carbon footprint of less than 0.36 kg CO2 per kg of acetic acid, and provides a green approach to enable both new industrial bioprocesses, and process intensification of existing industrial operations by (1) increasing the productivity and titer of the bioprocess via decreasing end-product inhibition, (2) minimizing downstream separation energy input to less than 20% of the heating value of the product, and (3) generating no waste products.},

doi = {10.1039/C7GC03747C},

journal = {Green Chemistry},

number = 8,

volume = 20,

place = {United States},

year = {Fri Mar 16 00:00:00 EDT 2018},

month = {Fri Mar 16 00:00:00 EDT 2018}

}

Web of Science

Figures / Tables:

Fig. 1: Proposed distillation based in situ product recovery (ISPR) system to recover free acids. Acids present in bioreactor (1) are extracted into an organic phase through a hollow fiber membrane contactor (2). The bioreactor media and cells are recycled (3) and the organic phase is passed into a distillationmore »

Fig. 1: Proposed distillation based in situ product recovery (ISPR) system to recover free acids. Acids present in bioreactor (1) are extracted into an organic phase through a hollow fiber membrane contactor (2). The bioreactor media and cells are recycled (3) and the organic phase is passed into a distillationmore »

Works referenced in this record:

Future directions forin-situ product removal (ISPR)

journal, January 2008

- Woodley, John M.; Bisschops, Marc; Straathof, Adrie J. J.

- Journal of Chemical Technology & Biotechnology, Vol. 83, Issue 2

Integrated acidogenic digestion and carboxylic acid separation by nanofiltration membranes for the lignocellulosic carboxylate platform

journal, September 2015

- Xiong, Boya; Richard, Tom L.; Kumar, Manish

- Journal of Membrane Science, Vol. 489

Propionic acid production by extractive fermentation. I. Solvent considerations

journal, February 1998

- Gu, Zhong; Glatz, Bonita A.; Glatz, Charles E.

- Biotechnology and Bioengineering, Vol. 57, Issue 4

Extraction of carboxylic acids with amine extractants. 1. Equilibria and law of mass action modeling

journal, July 1990

- Tamada, Janet A.; Kertes, A. Steven; King, C. Judson

- Industrial & Engineering Chemistry Research, Vol. 29, Issue 7

Separation of butanol from acetone–butanol–ethanol fermentation by a hybrid extraction–distillation process

journal, May 2011

- Kraemer, Korbinian; Harwardt, Andreas; Bronneberg, Rob

- Computers & Chemical Engineering, Vol. 35, Issue 5

Ethanol and isobutanol dehydration by heat-integrated distillation

journal, October 2016

- Grisales Díaz, Víctor Hugo; Olivar Tost, Gerard

- Chemical Engineering and Processing: Process Intensification, Vol. 108

Extraction Kinetics of Organic Acids with Tri-n-octylphosphine Oxide

journal, November 1996

- Matsumoto, Michiaki; Uenoyama, Shinji; Hano, Tadashi

- Journal of Chemical Technology & Biotechnology, Vol. 67, Issue 3

Reactive Extraction of Citric Acid Using Tri-n-octylamine in Nontoxic Natural Diluents: Part 1—Equilibrium Studies from Aqueous Solutions

journal, April 2012

- Keshav, Amit; Norge, Prakriti; Wasewar, Kailas L.

- Applied Biochemistry and Biotechnology, Vol. 167, Issue 2

Electrolytic Membrane Extraction Enables Production of Fine Chemicals from Biorefinery Sidestreams

journal, May 2014

- Andersen, Stephen J.; Hennebel, Tom; Gildemyn, Sylvia

- Environmental Science & Technology, Vol. 48, Issue 12

In situ product removal in fermentation systems: improved process performance and rational extractant selection

journal, October 2013

- Dafoe, Julian T.; Daugulis, Andrew J.

- Biotechnology Letters, Vol. 36, Issue 3

Recovery of carboxylic acids C1C3 with organophosphine oxide solvating extractants

journal, January 2005

- Wisniewski, Maciej; Pierzchalska, Magdalena

- Journal of Chemical Technology & Biotechnology, Vol. 80, Issue 12

Integrated bioprocesses

journal, June 2005

- Schügerl, Karl; Hubbuch, Jürgen

- Current Opinion in Microbiology, Vol. 8, Issue 3

In situ recovery of fumaric acid by intermittent adsorption with IRA-900 ion exchange resin for enhanced fumaric acid production by Rhizopus oryzae

journal, April 2015

- Zhang, Kun; Yang, Shang-Tian

- Biochemical Engineering Journal, Vol. 96

Bio-based production of C2-C6 platform chemicals

journal, July 2012

- Jang, Yu-Sin; Kim, Byoungjin; Shin, Jae Ho

- Biotechnology and Bioengineering, Vol. 109, Issue 10

Model-based design of a pilot-scale simulated moving bed for purification of citric acid from fermentation broth

journal, December 2009

- Wu, Jinglan; Peng, Qijun; Arlt, Wolfgang

- Journal of Chromatography A, Vol. 1216, Issue 50

Propionic and acetic acid pertraction through a multimembrane hybrid system containing TOPO or TBP

journal, March 2002

- Wódzki, Romuald; Nowaczyk, Jacek

- Separation and Purification Technology, Vol. 26, Issue 2-3

Conversion of l-lactate into n-caproate by a continuously fed reactor microbiome

journal, April 2016

- Kucek, Leo A.; Nguyen, Mytien; Angenent, Largus T.

- Water Research, Vol. 93

The Techno-Economic Basis for Coproduct Manufacturing To Enable Hydrocarbon Fuel Production from Lignocellulosic Biomass

journal, May 2016

- Biddy, Mary J.; Davis, Ryan; Humbird, David

- ACS Sustainable Chemistry & Engineering, Vol. 4, Issue 6

Water-Enhanced Solvation of Organic Solutes in Ketone and Ester Solvents

journal, May 1994

- Lee, Jane H.; Van Brunt, Vincent; King, C. Judson

- Industrial & Engineering Chemistry Research, Vol. 33, Issue 5

New insights in reactive extraction mechanisms of organic acids: An experimental approach for 3-hydroxypropionic acid extraction with tri-n-octylamine

journal, May 2017

- Chemarin, F.; Moussa, M.; Chadni, M.

- Separation and Purification Technology, Vol. 179

On the kinetics of the autoxidation of fats

journal, March 1993

- Brimberg, Ulla I.

- Journal of the American Oil Chemists' Society, Vol. 70, Issue 3

Characterization of gas stripping and its integration with acetone–butanol–ethanol fermentation for high-efficient butanol production and recovery

journal, February 2014

- Xue, Chuang; Du, Guang-Qing; Sun, Jian-Xin

- Biochemical Engineering Journal, Vol. 83

Recovery of carboxylic acids produced by fermentation

journal, September 2014

- López-Garzón, Camilo S.; Straathof, Adrie J. J.

- Biotechnology Advances, Vol. 32, Issue 5

Mixed Carboxylic Acid Production by Megasphaera elsdenii from Glucose and Lignocellulosic Hydrolysate

journal, March 2017

- Nelson, Robert; Peterson, Darren; Karp, Eric

- Fermentation, Vol. 3, Issue 1

Equilibrium and Kinetics of the Extraction of Propionic Acid Using Tri- n -Octylphosphineoxide

journal, September 2008

- Keshav, A.; Wasewar, K. L.; Chand, S.

- Chemical Engineering & Technology, Vol. 31, Issue 9

Novel extractants for the recovery of fermentation derived lactic acid

journal, June 2013

- Krzyżaniak, Agnieszka; Leeman, Michel; Vossebeld, Frank

- Separation and Purification Technology, Vol. 111

Advances in in-situ product recovery (ISPR) in whole cell biotechnology during the last decade

journal, November 2014

- Van Hecke, Wouter; Kaur, Guneet; De Wever, Heleen

- Biotechnology Advances, Vol. 32, Issue 7

Applied in situ product recovery in ABE fermentation

journal, March 2017

- Outram, Victoria; Lalander, Carl‐Axel; Lee, Jonathan G. M.

- Biotechnology Progress, Vol. 33, Issue 3

Extractive Fermentation for Enhanced Propionic Acid Production from Lactose by Propionibacterium acidipropionici

journal, June 1998

- Jin, Z.; Yang, S. -T.

- Biotechnology Progress, Vol. 14, Issue 3

Interfacial Mass Transfer in the Reactive Extraction Process of Succinic Acid from Viscous Aqueous Solutions

journal, May 2014

- Carlescu, A.; Blaga, A. C.; Galaction, A. -I.

- Separation Science and Technology, Vol. 49, Issue 7

Mass transfer coefficients in reactive extraction of lactic acid from fermentation broths in hollow-fibre membranes

journal, October 1999

- Scheler, Christian; Popovic, Milan K.; Iannotti, Eugene L.

- The Canadian Journal of Chemical Engineering, Vol. 77, Issue 5

Energy and Environmental Aspects of Using Corn Stover for Fuel Ethanol

journal, June 2003

- Sheehan, John; Aden, Andy; Paustian, Keith

- Journal of Industrial Ecology, Vol. 7, Issue 3-4

Life cycle analysis of biochemical cellulosic ethanol under multiple scenarios

journal, June 2014

- Murphy, Colin W.; Kendall, Alissa

- GCB Bioenergy, Vol. 7, Issue 5

Noncatalytic esterification of oleic acid in ethanol

journal, June 2010

- Pinnarat, Tanawan; Savage, Phillip E.

- The Journal of Supercritical Fluids, Vol. 53, Issue 1-3

Transformation of Biomass into Commodity Chemicals Using Enzymes or Cells

journal, August 2013

- Straathof, Adrie J. J.

- Chemical Reviews, Vol. 114, Issue 3

In Situ Product Removal as a Tool for Bioprocessing

journal, September 1993

- Freeman, Amihay; Woodley, John M.; Lilly, Malcolm D.

- Nature Biotechnology, Vol. 11, Issue 9

Top value platform chemicals: bio-based production of organic acids

journal, December 2015

- Becker, Judith; Lange, Anna; Fabarius, Jonathan

- Current Opinion in Biotechnology, Vol. 36

Production of drop-in fuels from biomass at high selectivity by combined microbial and electrochemical conversion

journal, January 2017

- Urban, Carolin; Xu, Jiajie; Sträuber, Heike

- Energy & Environmental Science, Vol. 10, Issue 10

Back extraction of propionic acid from loaded organic phase

journal, May 2010

- Keshav, Amit; Wasewar, Kailas L.

- Chemical Engineering Science, Vol. 65, Issue 9

Chain elongation with reactor microbiomes: upgrading dilute ethanol to medium-chain carboxylates

journal, January 2012

- Agler, Matthew T.; Spirito, Catherine M.; Usack, Joseph G.

- Energy & Environmental Science, Vol. 5, Issue 8

Effective lactic acid production by two-stage extractive fermentation

journal, January 1995

- Honda, Hiroyuki; Toyama, Yoshio; Takahashi, Hiroshi

- Journal of Fermentation and Bioengineering, Vol. 79, Issue 6

Membrane-based extractive fermentation to produce propionic and acetic acids: Toxicity and mass transfer considerations

journal, January 1995

- Solichien, M. S.; O'Brien, D.; Hammond, E. G.

- Enzyme and Microbial Technology, Vol. 17, Issue 1

Recovery and separation of organic acids by membrane-based solvent extraction and pertraction

journal, February 2005

- Schlosser, Š.; Kertész, R.; Marták, J.

- Separation and Purification Technology, Vol. 41, Issue 3

Extraction Equilibria of Propionic and Butyric Acids with Tri- n -octylphosphine Oxide/Diluent Systems

journal, November 2009

- Bilgin, Mehmet; Arısoy, Çiğdem; Kırbaşlar, Ş. İsmail

- Journal of Chemical & Engineering Data, Vol. 54, Issue 11

Biobased organic acids production by metabolically engineered microorganisms

journal, February 2016

- Chen, Yun; Nielsen, Jens

- Current Opinion in Biotechnology, Vol. 37

Extractive fermentation for butyric acid production from glucose byClostridium tyrobutyricum

journal, February 2003

- Wu, Zetang; Yang, Shang-Tian

- Biotechnology and Bioengineering, Vol. 82, Issue 1

Intensification of enzymatic conversion of glucose to lactic acid by reactive extraction

journal, August 2003

- Wasewar, Kailas L.; Pangarkar, Vishwas G.; Heesink, A. Bert M.

- Chemical Engineering Science, Vol. 58, Issue 15

Nanofiltration-Enabled In Situ Solvent and Reagent Recycle for Sustainable Continuous-Flow Synthesis

journal, August 2017

- Fodi, Tamas; Didaskalou, Christos; Kupai, Jozsef

- ChemSusChem, Vol. 10, Issue 17

Separation technologies for the recovery and dehydration of alcohols from fermentation broths

journal, November 2008

- Vane, Leland M.

- Biofuels, Bioproducts and Biorefining, Vol. 2, Issue 6

Biotechnological production of citric acid

journal, January 2010

- Max, Belén; Salgado, José Manuel; Rodríguez, Noelia

- Brazilian Journal of Microbiology, Vol. 41, Issue 4

Removal of Acetic acid with Amine Extractants from Fermentation Broth Using Hydrophobic Hollow-Fiber Membrane Contactor

journal, February 2001

- Lee, Young Moo; Kang, Jong Seok; Nam, Sang Yong

- Separation Science and Technology, Vol. 36, Issue 3

Valorisation of agricultural waste with an adsorption/nanofiltration hybrid process: from materials to sustainable process design

journal, January 2017

- Didaskalou, Christos; Buyuktiryaki, Sibel; Kecili, Rustem

- Green Chemistry, Vol. 19, Issue 13

Economic and energetic analysis of capturing CO2 from ambient air

journal, December 2011

- House, K. Z.; Baclig, A. C.; Ranjan, M.

- Proceedings of the National Academy of Sciences, Vol. 108, Issue 51

Waste to bioproduct conversion with undefined mixed cultures: the carboxylate platform

journal, February 2011

- Agler, Matthew T.; Wrenn, Brian A.; Zinder, Stephen H.

- Trends in Biotechnology, Vol. 29, Issue 2

Toxicity of organic solvents used in situ in microbial fermentation

journal, April 1995

- Marták, Ján; Rosenberg, Michal; Schlosser, Štefan

- Biotechnology Techniques, Vol. 9, Issue 4

The E factor 25 years on: the rise of green chemistry and sustainability

journal, January 2017

- Sheldon, Roger A.

- Green Chemistry, Vol. 19, Issue 1

Works referencing / citing this record:

Ionic liquid-high performance extractive approach to recover carotenoids from Bactris gasipaes fruits

journal, January 2019

- de Souza Mesquita, Leonardo M.; Ventura, Sónia P. M.; Braga, Anna R. C.

- Green Chemistry, Vol. 21, Issue 9

Assessing the stability and techno-economic implications for wet storage of harvested microalgae to manage seasonal variability

journal, April 2019

- Wendt, Lynn M.; Kinchin, Christopher; Wahlen, Bradley D.

- Biotechnology for Biofuels, Vol. 12, Issue 1

Eco-efficient recovery of bio-based volatile C2–6 fatty acids

journal, April 2019

- Woo, Hee Chul; Kim, Young Han

- Biotechnology for Biofuels, Vol. 12, Issue 1

In situ product recovery of bio-based ethyl esters via hybrid extraction-distillation

journal, January 2019

- Saboe, Patrick O.; Monroe, Hanna R.; Michener, William E.

- Green Chemistry, Vol. 21, Issue 19

Revisiting alkaline aerobic lignin oxidation

journal, January 2018

- Schutyser, Wouter; Kruger, Jacob S.; Robinson, Allison M.

- Green Chemistry, Vol. 20, Issue 16

Figures / Tables found in this record:

Search WorldCat to find libraries that may hold this journal

Search WorldCat to find libraries that may hold this journal