Pellet-clad mechanical interaction screening using VERA applied to Watts Bar Unit 1, Cycles 1–3

Abstract

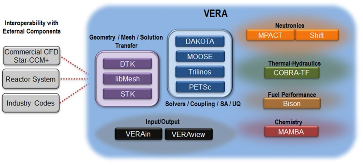

The Consortium for Advanced Simulation of Light Water Reactors (CASL) aims to provide high-fidelity multiphysics simulations of light water nuclear reactors. To accomplish this, CASL is developing the Virtual Environment for Reactor Applications (VERA), which is a suite of code packages for thermal hydraulics, neutron transport, fuel performance, and coolant chemistry. As VERA continues to grow and expand, there has been an increased focus on incorporating fuel performance analysis methods. One of the primary goals of CASL is to estimate local cladding failure probability through pellet-clad interaction, which consists of both pellet-clad mechanical interaction (PCMI) and stress corrosion cracking. Estimating clad failure is important to preventing release of fission products to the primary system and accurate estimates could prove useful in establishing less conservative power ramp rates or when considering load-follow operations.While this capability is being pursued through several different approaches, the procedure presented in this article focuses on running independent fuel performance calculations with BISON using a file-based one-way coupling based on multicycle output data from high fidelity, pin-resolved coupled neutron transport–thermal hydraulics simulations. This type of approach is consistent with traditional fuel performance analysis methods, which are typically separate from core simulation analyses. A more tightly coupled approachmore »

- Authors:

-

- Oak Ridge National Lab. (ORNL), Oak Ridge, TN (United States)

- Sandia National Lab. (SNL-NM), Albuquerque, NM (United States)

- Idaho National Lab. (INL), Idaho Falls, ID (United States)

- Publication Date:

- Research Org.:

- Oak Ridge National Lab. (ORNL), Oak Ridge, TN (United States). Oak Ridge Leadership Computing Facility (OLCF)

- Sponsoring Org.:

- USDOE Office of Science (SC); USDOE Office of Nuclear Energy (NE)

- OSTI Identifier:

- 1429216

- Alternate Identifier(s):

- OSTI ID: 1549000

- Grant/Contract Number:

- AC05-00OR22725; AC07-05ID14517

- Resource Type:

- Accepted Manuscript

- Journal Name:

- Nuclear Engineering and Design

- Additional Journal Information:

- Journal Volume: 327; Journal Issue: C; Journal ID: ISSN 0029-5493

- Publisher:

- Elsevier

- Country of Publication:

- United States

- Language:

- English

- Subject:

- 42 ENGINEERING; 22 GENERAL STUDIES OF NUCLEAR REACTORS; BISON; Fuel performance; PCMI; VERA; CASL

Citation Formats

Stimpson, Shane, Powers, Jeffrey, Clarno, Kevin, Pawlowski, Roger, Gardner, Russell, Novascone, Stephen, Gamble, Kyle, and Williamson, Richard. Pellet-clad mechanical interaction screening using VERA applied to Watts Bar Unit 1, Cycles 1–3. United States: N. p., 2017.

Web. doi:10.1016/j.nucengdes.2017.12.015.

Stimpson, Shane, Powers, Jeffrey, Clarno, Kevin, Pawlowski, Roger, Gardner, Russell, Novascone, Stephen, Gamble, Kyle, & Williamson, Richard. Pellet-clad mechanical interaction screening using VERA applied to Watts Bar Unit 1, Cycles 1–3. United States. https://doi.org/10.1016/j.nucengdes.2017.12.015

Stimpson, Shane, Powers, Jeffrey, Clarno, Kevin, Pawlowski, Roger, Gardner, Russell, Novascone, Stephen, Gamble, Kyle, and Williamson, Richard. Fri .

"Pellet-clad mechanical interaction screening using VERA applied to Watts Bar Unit 1, Cycles 1–3". United States. https://doi.org/10.1016/j.nucengdes.2017.12.015. https://www.osti.gov/servlets/purl/1429216.

@article{osti_1429216,

title = {Pellet-clad mechanical interaction screening using VERA applied to Watts Bar Unit 1, Cycles 1–3},

author = {Stimpson, Shane and Powers, Jeffrey and Clarno, Kevin and Pawlowski, Roger and Gardner, Russell and Novascone, Stephen and Gamble, Kyle and Williamson, Richard},

abstractNote = {The Consortium for Advanced Simulation of Light Water Reactors (CASL) aims to provide high-fidelity multiphysics simulations of light water nuclear reactors. To accomplish this, CASL is developing the Virtual Environment for Reactor Applications (VERA), which is a suite of code packages for thermal hydraulics, neutron transport, fuel performance, and coolant chemistry. As VERA continues to grow and expand, there has been an increased focus on incorporating fuel performance analysis methods. One of the primary goals of CASL is to estimate local cladding failure probability through pellet-clad interaction, which consists of both pellet-clad mechanical interaction (PCMI) and stress corrosion cracking. Estimating clad failure is important to preventing release of fission products to the primary system and accurate estimates could prove useful in establishing less conservative power ramp rates or when considering load-follow operations.While this capability is being pursued through several different approaches, the procedure presented in this article focuses on running independent fuel performance calculations with BISON using a file-based one-way coupling based on multicycle output data from high fidelity, pin-resolved coupled neutron transport–thermal hydraulics simulations. This type of approach is consistent with traditional fuel performance analysis methods, which are typically separate from core simulation analyses. A more tightly coupled approach is currently being developed, which is the ultimate target application in CASL.Recent work simulating 12 cycles of Watts Bar Unit 1 with VERA core simulator are capitalized upon, and quarter-core BISON results for parameters of interest to PCMI (maximum centerline fuel temperature, maximum clad hoop stress, and minimum gap size) are presented for Cycles 1–3. In conclusion, based on these results, this capability demonstrates its value and how it could be used as a screening tool for gathering insight into PCMI, singling out limiting rods for further, more detailed analysis.},

doi = {10.1016/j.nucengdes.2017.12.015},

journal = {Nuclear Engineering and Design},

number = C,

volume = 327,

place = {United States},

year = {Fri Dec 22 00:00:00 EST 2017},

month = {Fri Dec 22 00:00:00 EST 2017}

}

Web of Science

Figures / Tables:

Fig. 1: Codes within the Virtual Environment for Reactor Applications.

Fig. 1: Codes within the Virtual Environment for Reactor Applications.

Works referenced in this record:

Stability and accuracy of 3D neutron transport simulations using the 2D/1D method in MPACT

journal, December 2016

- Collins, Benjamin; Stimpson, Shane; Kelley, Blake W.

- Journal of Computational Physics, Vol. 326

Pellet-clad interaction (PCI) failures of zirconium alloy fuel cladding — A review

journal, August 1990

- Cox, B.

- Journal of Nuclear Materials, Vol. 172, Issue 3

MOOSE: A parallel computational framework for coupled systems of nonlinear equations

journal, October 2009

- Gaston, Derek; Newman, Chris; Hansen, Glen

- Nuclear Engineering and Design, Vol. 239, Issue 10

VERA Core Simulator Methodology for Pressurized Water Reactor Cycle Depletion

journal, January 2017

- Kochunas, Brendan; Collins, Benjamin; Stimpson, Shane

- Nuclear Science and Engineering, Vol. 185, Issue 1

The Virtual Environment for Reactor Applications (VERA): Design and architecture

journal, December 2016

- Turner, John A.; Clarno, Kevin; Sieger, Matt

- Journal of Computational Physics, Vol. 326

A new fission-gas release model

journal, August 1983

- White, R. J.; Tucker, M. O.

- Journal of Nuclear Materials, Vol. 118, Issue 1

Multidimensional multiphysics simulation of nuclear fuel behavior

journal, April 2012

- Williamson, R. L.; Hales, J. D.; Novascone, S. R.

- Journal of Nuclear Materials, Vol. 423, Issue 1-3

Works referencing / citing this record:

The technological challenge for current generation nuclear reactors

journal, September 2019

- D’Auria, Francesco; Debrecin, Nenad; Glaeser, Horst

- Nuclear Energy and Technology, Vol. 5, Issue 3

Figures / Tables found in this record:

Search WorldCat to find libraries that may hold this journal

Search WorldCat to find libraries that may hold this journal