Influence of humidity, temperature, and annealing on microstructure and tensile properties of electrospun polyacrylonitrile nanofibers

- Argonne National Lab. (ANL), Lemont, IL (United States)

- Univ. of Oklahoma, Norman, OK (United States)

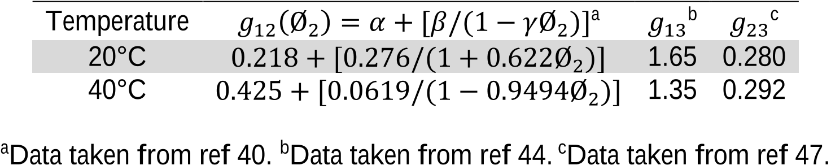

This study investigates the microstructure and mechanical properties of electrospun nanofibers from polyacrylonitrile (PAN)-dimethylformamide (DMF) solution at different relative humidity (RH) in the range from 14% to 60% and two different temperatures (20 °C and 40 °C). Nanofibers produced at low RH (22% or less at 20 °C) exhibit relatively smooth surface and solid core, whereas at higher RH (30% or higher at 20 °C) rough surface and porous core are observed. The resulting morphology is explained by means of H2O/DMF/PAN ternary phase diagram. At higher RH, the water diffusion into polymer-solution jet brings thermodynamic instability into the system leading to separation of polymer-rich phase and polymer-lean phase, where the later contributes to porosity. Higher process temperature (40 °C) yields larger miscibility area in the ternary phase diagram leading to formation of porous structure at relatively higher RH (40%). Tensile strength of nanofibrous yarns is found to vary from 80 MPa to 130 MPa depending on the processing temperature and RH. The amount of porosity is found to affect the tensile properties of nanofibers most significantly, although diameter and crystallinity play important role. Annealing is found to alleviate surface roughness and porosity and increase crystallinity. Furthermore, tensile strength of nanofibrous yarns is found to improve by up to 25% after annealing.

- Research Organization:

- Argonne National Lab. (ANL), Argonne, IL (United States)

- Sponsoring Organization:

- USDOE Office of Science (SC)

- Grant/Contract Number:

- AC02-06CH11357

- OSTI ID:

- 1489820

- Journal Information:

- Polymer Engineering and Science, Vol. 58, Issue 6; ISSN 0032-3888

- Publisher:

- WileyCopyright Statement

- Country of Publication:

- United States

- Language:

- English

Web of Science

Preparation and performance of three-layered structure composite membrane for heavy metal ions and hazardous dyes rejection

|

journal | October 2018 |

A Review on the Secondary Surface Morphology of Electrospun Nanofibers: Formation Mechanisms, Characterizations, and Applications

|

journal | January 2020 |

On the Nanoscale Mapping of the Mechanical and Piezoelectric Properties of Poly (L-Lactic Acid) Electrospun Nanofibers

|

journal | January 2020 |

Similar Records

Electrical bending actuation of gold-films with nanotextured surfaces

Carbon Nanotube Dispersion in Solvents and Polymer Solutions: Mechanisms, Assembly, and Preferences