In situ synchrotron X-ray diffraction investigations of the physical mechanism of ultra-low strain hardening in Ti-30Zr-10Nb alloy

Journal Article

·

· Acta Materialia

- Univ. of Science and Technology Beijing, Beijing (China). State Key Lab. for Advanced Metals and Materials

- Beihang Univ, Beijing (China). School of Materials Science and Engineering

- Argonne National Lab. (ANL), Argonne, IL (United States). X-ray Science Division

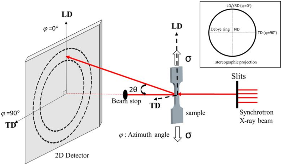

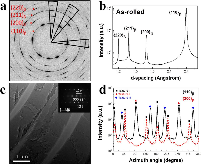

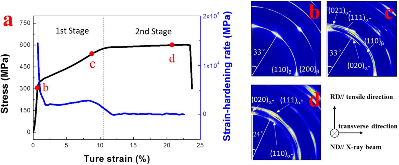

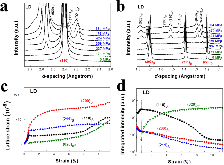

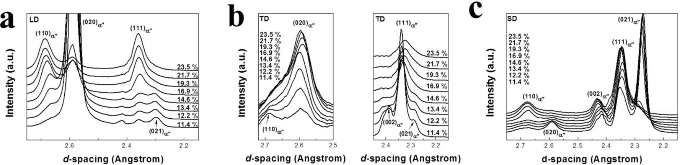

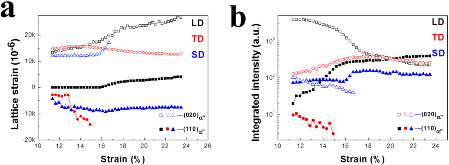

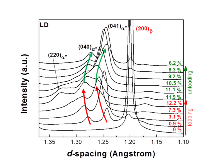

A warm-rolled, metastable beta-type Ti-30Zr-10Nb alloy exhibited a peculiar two-stage yielding behavior under uniaxial tensile loading, showing a first plastic stage with obvious strain hardening at 0.4%-10.4% strain and a second plastic stage with ultra-low strain hardening at 10.4%-23.5% strain. In situ high-energy X-ray diffraction (HE-XRD) was used to reveal the stress-induced martensitic transformation scenarios and physical mechanism of the different strain hardening rates. It was found that the deformation-induced phase transformation dominated the onset of the first plastic stage corresponding to the selection of favorable martensitic variants, and their elastic interaction contributed to the obvious strain hardening. HE-XRD experiments further verified that the ultra-low strain hardening rate in the second plastic stage was related to an interesting superelasticity of the martensite, which was characterized by the reversible, stress-induced reorientation of the martensite variants. This reorientation of the martensite variants was primarily due to the rigid lattice rotation of similar to 23 degrees about the [110](α '') axis toward the tensile direction. Here, our investigations provide in-depth understanding of the mechanism of the excellent plasticity with ultra-low strain hardening in beta-type titanium alloys.

- Research Organization:

- Argonne National Laboratory (ANL), Argonne, IL (United States)

- Sponsoring Organization:

- National Key Research and Development Program of China; National Natural Science Foundation of China (NNSFC); USDOE Office of Science (SC), Basic Energy Sciences (BES); USDOE Office of Science (SC), Basic Energy Sciences (BES) (SC-22)

- Grant/Contract Number:

- AC02-06CH11357

- OSTI ID:

- 1480849

- Alternate ID(s):

- OSTI ID: 22744684

OSTI ID: 1496406

- Journal Information:

- Acta Materialia, Journal Name: Acta Materialia Journal Issue: C Vol. 154; ISSN 1359-6454

- Publisher:

- ElsevierCopyright Statement

- Country of Publication:

- United States

- Language:

- English

Martensitic transformation, shape memory effect and superelasticity of Ti–xZr–(30–x)Nb–4Ta alloys

|

journal | September 2019 |

Similar Records

Phase transformation and microstructure evolution of the deformed Ti-30Zr-5Nb shape memory alloy

Influence of work hardening and heat treatment on the substructure and deformation behavior of TiNi shape memory alloys

Journal Article

·

Sat Apr 15 00:00:00 EDT 2017

· Materials Characterization

·

OSTI ID:22689737

Influence of work hardening and heat treatment on the substructure and deformation behavior of TiNi shape memory alloys

Journal Article

·

Mon May 01 00:00:00 EDT 1995

· Scripta Metallurgica et Materialia

·

OSTI ID:64359