Fuel relocation recovery implementation in Bison

- Idaho National Lab. (INL), Idaho Falls, ID (United States)

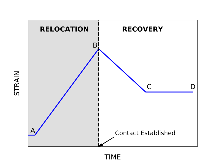

During the initial rise to power in light water reactors (LWR), thermal gradients within a pellet cause radial and axial cracks to form in the fuel. The effect of these cracks is to reduce the pellet-cladding gap and accelerate the interaction between the fuel and cladding. This process is known as fuel relocation and may also include contributions from pellet eccentricity and cladding ovality. Since the cladding experiences both elevated temperatures and high external pressure due to the coolant, the cladding typically creeps inward further reducing the pellet-cladding gap. Once the gap is closed and pellet cladding mechanical interaction (PCMI) begins, both the thermal and mechanical behavior of the fuel is affected. The compressive forces exerted on the fuel due to contact with the cladding cause the fractured fuel sections to move back toward their original position which is termed relocation recovery. A model for this phenomenon is implemented in the BISON fuel performance code and applied to a set of validation test cases. In conclusion, the predicted fuel rod diameter is compared to experimental measurements to evaluate the influence of relocation recovery over a range of operating conditions.

- Research Organization:

- Idaho National Lab. (INL), Idaho Falls, ID (United States)

- Sponsoring Organization:

- USDOE Office of Nuclear Energy (NE)

- Grant/Contract Number:

- AC07-05ID14517

- OSTI ID:

- 1480510

- Report Number(s):

- INL/JOU-18-45000-Rev000

- Journal Information:

- Journal of Nuclear Materials, Vol. 511, Issue C; ISSN 0022-3115

- Publisher:

- ElsevierCopyright Statement

- Country of Publication:

- United States

- Language:

- English

Web of Science

Similar Records

BISON Fuel Performance Analysis of IFA-796 Rod 3 & 4 and Investigation of the Impact of Fuel Creep

BISON Contact Algorithm Improvements in Support of Pellet Cladding Mechanical Interaction Modeling