Comparison of structure, morphology, and leach characteristics of multi-phase ceramics produced via melt processing and hot isostatic pressing

- Savannah River Site (SRS), Aiken, SC (United States). Savannah River National Lab. (SRNL)

- Clemson Univ., SC (United States)

- Australian Nuclear Science and Technology Organisation (ANSTO), Lucas Heights, NSW (Australia)

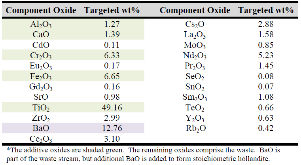

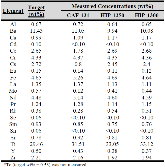

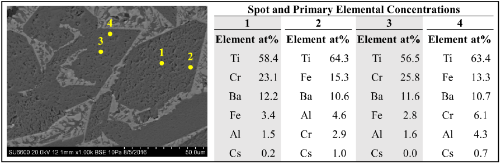

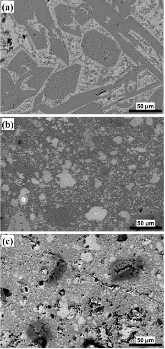

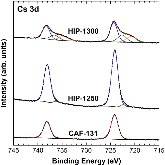

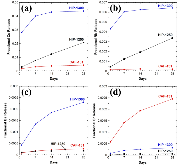

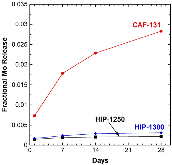

Melt processing of multi-phase ceramic waste forms offers potential advantages over traditional solid-state synthesis methods given both the prevalence of melters currently in use and the ability to reduce the possibility of airborne radionuclide contamination. In this work, multi-phase ceramics with a targeted hollandite composition of Ba1.0Cs0.3Cr1.0Al0.3Fe1.0Ti5.7O16 were fabricated by melt processing at 1675 °C and hot isostatic pressing (HIP) at 1250 and 1300 °C. X-ray diffraction analysis (XRD) confirmed hollandite as the major phase in all specimens. Zirconolite/pyrochlore peaks and weaker perovskite reflections were observed after melt processing, while HIP samples displayed prominent perovskite peaks and low-intensity zirconolite reflections. Melt processing produced specimens with large (>50 μm) well-defined hollandite grains, while HIP yielded samples with a more fine-grained morphology. Elemental analysis showed “islands” rich in Cs and Ti across the surface of the 1300 °C HIP sample, suggesting partial melting and partitioning of Cs into multiple phases. Photoemission data revealed multiple Cs 3d spin-orbit pairs for the HIP samples, with the lower binding energy doublets likely corresponding to Cs located in more leachable phases. Among all specimens examined, the melt-processed sample exhibited the lowest fractional release rates for Rb and Cs. However, the retention of Sr and Mo was greater in the HIP specimens.

- Research Organization:

- Savannah River Site (SRS), Aiken, SC (United States)

- Sponsoring Organization:

- USDOE

- Grant/Contract Number:

- AC09-08SR22470

- OSTI ID:

- 1427454

- Report Number(s):

- SRNL-STI--2017-00651; PII: S0022311517314241

- Journal Information:

- Journal of Nuclear Materials, Journal Name: Journal of Nuclear Materials Journal Issue: C Vol. 502; ISSN 0022-3115

- Publisher:

- ElsevierCopyright Statement

- Country of Publication:

- United States

- Language:

- English

Synthesis and phase structure of (Cs0.8−xBa0.4+x)(Al3+1.6+ xTi4+6.4− x)O16 ceramics using sol-spray pyrolysis route for immobilizing radioactive cesium

|

journal | May 2019 |

Thermodynamic assessment of the hollandite high‐level radioactive waste form

|

journal | April 2019 |

Similar Records

Radiation damage of hollandite in multiphase ceramic waste forms