Experimental Characterization and Numerical Modeling of the Interaction Between Carbon Fiber Composite Prepregs During a Preforming Process

- Northwestern Univ., Evanston, IL (United States)

- Northwestern Univ., Evanston, IL (United States); Harbin Inst. of Technology (China)

- Ford Motor Company, Dearborn, MI (United States)

- Dow Chemical Company, Auburn Hills, MI (United States)

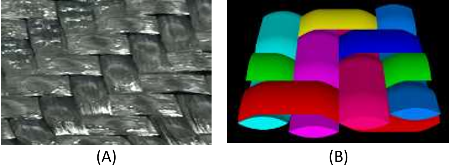

We report carbon fiber reinforced composites have received growing attention because of their superior performance and high potential for lightweight systems. An economic method to manufacture the parts made of these composites is a sequence of forming followed by a compression molding. The first step in this sequence is called preforming that forms the prepreg, which is the fabric impregnated with the uncured resin, to the product geometry, while the molding process cures the resin. Slip between different prepreg layers is observed in the preforming step, and it is believed to have a non-negligible impact on the resulting geometry. This paper reports a method to characterize the interaction between different prepreg layers, which should be valuable for future predictive modeling and design optimization. An experimental device was built to evaluate the interactions with respect to various industrial production conditions. The experimental results were analyzed for an in-depth understanding about how temperature, relative sliding speed, and fiber orientation affect the tangential interaction between two prepreg layers. Moreover, a hydro-lubricant model was introduced to study the relative motion mechanism of this fabric-resin-fabric system, and the results agreed well with the experiment data. Lastly, the interaction factors obtained from this research will be implemented in a preforming process finite element simulation model.

- Research Organization:

- Ford Motor Company, Detroit, MI (United States)

- Sponsoring Organization:

- USDOE Office of Energy Efficiency and Renewable Energy (EERE), Vehicle Technologies Office (EE-3V)

- Grant/Contract Number:

- EE0006867

- OSTI ID:

- 1504734

- Journal Information:

- Journal of Manufacturing Science and Engineering, Vol. 140, Issue 8; ISSN 1087-1357

- Publisher:

- ASMECopyright Statement

- Country of Publication:

- United States

- Language:

- English

Web of Science

Similar Records

In-situ sensor monitoring of resin film infusion of advanced fiber architecture preforms

A numerical Bayesian-calibrated characterization method for multiscale prepreg preforming simulations with tension-shear coupling