Chemical Transformations of Poplar Lignin during Cosolvent Enhanced Lignocellulosic Fractionation Process

Abstract

Converting lignocellulosic biomass to biofuels and bioproducts is significantly hindered by the innate recalcitrance of biomass to chemical and biological breakdown, and it usually requires a pretreatment stage in order to improve conversion yields. A promising novel pretreatment named Cosolvent Enhanced Lignocellulosic Fractionation (CELF) involving dilute acid treatment of biomass in a THF–water mixture was recently developed to overcome biomass recalcitrance. Detailed elucidation of physicochemical structures of the fractionated lignin that is precipitated from CELF pretreatment of hardwood poplar, also called CELF lignin, reveals transformations in its molecular weights, monolignol composition, and hydroxyl group content. Isolated CELF lignin revealed dramatic reductions in its molecular weight by up to ~90% compared with untreated native lignin. Furthermore, CELF lignin’s β-O-4 interunit linkages were extensively cleaved after CELF pretreatment as indicated by a semiquantitative HSQC NMR analysis. This is further evidenced by a 31P NMR analysis showing a significant decrease in aliphatic OH groups due to the oxidation of lignin side chains, whereas the content of total phenolic OH groups in CELF lignin significantly increased due to cleavage of interunit linkages. In conclusion, the CELF process generated a uniquely tunable and highly pure lignin feedstock of low content aryl ether linkages, low molecularmore »

- Authors:

-

- Department of Chemical and Biomolecular Engineering, University of Tennessee Knoxville, Knoxville, Tennessee 37996, United States

- Bourns College of Engineering—Center of Environmental and Research Technology (CE-CERT), University of California, Riverside, California 92507, United States; Department of Chemical and Environmental Engineering, Bourns College of Engineering, University of California, Riverside, California 92521, United States

- Bourns College of Engineering—Center of Environmental and Research Technology (CE-CERT), University of California, Riverside, California 92507, United States

- Biosciences Division, Oak Ridge National Laboratory, Oak Ridge, Tennessee 37831, United States

- Department of Chemical and Environmental Engineering, Bourns College of Engineering, University of California, Riverside, California 92521, United States; Department of Chemical Engineering, University of California, Santa Barbara, Santa Barbara, California 93106, United States

- Department of Chemical and Biomolecular Engineering, University of Tennessee Knoxville, Knoxville, Tennessee 37996, United States; Biosciences Division, Oak Ridge National Laboratory, Oak Ridge, Tennessee 37831, United States; Department of Forestry, Wildlife, and Fisheries, Center for Renewable Carbon, The University of Tennessee Knoxville, Institute of Agriculture, Knoxville, Tennessee 37996, United States

- Publication Date:

- Research Org.:

- Univ. of California, Riverside, CA (United States); Oak Ridge National Laboratory (ORNL), Oak Ridge, TN (United States)

- Sponsoring Org.:

- USDOE Office of Energy Efficiency and Renewable Energy (EERE)

- OSTI Identifier:

- 1581903

- Alternate Identifier(s):

- OSTI ID: 1513423

- Grant/Contract Number:

- EE0007006; AC05-00OR22725

- Resource Type:

- Accepted Manuscript

- Journal Name:

- ACS Sustainable Chemistry & Engineering

- Additional Journal Information:

- Journal Volume: 6; Journal Issue: 7; Journal ID: ISSN 2168-0485

- Publisher:

- American Chemical Society (ACS)

- Country of Publication:

- United States

- Language:

- English

- Subject:

- 09 BIOMASS FUELS; Pretreatment; Organic polymers; Biomass; Aromatic compounds; Biopolymers; Antioxidant; Biomass recalcitrance; Cosolvent Enhanced Lignocellulosic Fractionation; Lignin valorization

Citation Formats

Meng, Xianzhi, Parikh, Aakash, Seemala, Bhogeswararao, Kumar, Rajeev, Pu, Yunqiao, Christopher, Phillip, Wyman, Charles E., Cai, Charles M., and Ragauskas, Arthur J. Chemical Transformations of Poplar Lignin during Cosolvent Enhanced Lignocellulosic Fractionation Process. United States: N. p., 2018.

Web. doi:10.1021/acssuschemeng.8b01028.

Meng, Xianzhi, Parikh, Aakash, Seemala, Bhogeswararao, Kumar, Rajeev, Pu, Yunqiao, Christopher, Phillip, Wyman, Charles E., Cai, Charles M., & Ragauskas, Arthur J. Chemical Transformations of Poplar Lignin during Cosolvent Enhanced Lignocellulosic Fractionation Process. United States. https://doi.org/10.1021/acssuschemeng.8b01028

Meng, Xianzhi, Parikh, Aakash, Seemala, Bhogeswararao, Kumar, Rajeev, Pu, Yunqiao, Christopher, Phillip, Wyman, Charles E., Cai, Charles M., and Ragauskas, Arthur J. Thu .

"Chemical Transformations of Poplar Lignin during Cosolvent Enhanced Lignocellulosic Fractionation Process". United States. https://doi.org/10.1021/acssuschemeng.8b01028. https://www.osti.gov/servlets/purl/1581903.

@article{osti_1581903,

title = {Chemical Transformations of Poplar Lignin during Cosolvent Enhanced Lignocellulosic Fractionation Process},

author = {Meng, Xianzhi and Parikh, Aakash and Seemala, Bhogeswararao and Kumar, Rajeev and Pu, Yunqiao and Christopher, Phillip and Wyman, Charles E. and Cai, Charles M. and Ragauskas, Arthur J.},

abstractNote = {Converting lignocellulosic biomass to biofuels and bioproducts is significantly hindered by the innate recalcitrance of biomass to chemical and biological breakdown, and it usually requires a pretreatment stage in order to improve conversion yields. A promising novel pretreatment named Cosolvent Enhanced Lignocellulosic Fractionation (CELF) involving dilute acid treatment of biomass in a THF–water mixture was recently developed to overcome biomass recalcitrance. Detailed elucidation of physicochemical structures of the fractionated lignin that is precipitated from CELF pretreatment of hardwood poplar, also called CELF lignin, reveals transformations in its molecular weights, monolignol composition, and hydroxyl group content. Isolated CELF lignin revealed dramatic reductions in its molecular weight by up to ~90% compared with untreated native lignin. Furthermore, CELF lignin’s β-O-4 interunit linkages were extensively cleaved after CELF pretreatment as indicated by a semiquantitative HSQC NMR analysis. This is further evidenced by a 31P NMR analysis showing a significant decrease in aliphatic OH groups due to the oxidation of lignin side chains, whereas the content of total phenolic OH groups in CELF lignin significantly increased due to cleavage of interunit linkages. In conclusion, the CELF process generated a uniquely tunable and highly pure lignin feedstock of low content aryl ether linkages, low molecular weight, and high amount of phenolic hydroxyl groups, suitable for its development into fuels, chemicals, and materials.},

doi = {10.1021/acssuschemeng.8b01028},

journal = {ACS Sustainable Chemistry & Engineering},

number = 7,

volume = 6,

place = {United States},

year = {Thu May 24 00:00:00 EDT 2018},

month = {Thu May 24 00:00:00 EDT 2018}

}

Web of Science

Figures / Tables:

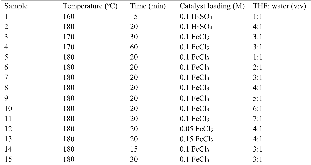

Table 1: List of pretreatment conditions applied in this work for CELF process of poplar.

Table 1: List of pretreatment conditions applied in this work for CELF process of poplar.

Works referenced in this record:

Characterization of Lignin Streams during Bionic Liquid-Based Pretreatment from Grass, Hardwood, and Softwood

journal, January 2018

- Dutta, Tanmoy; Papa, Gabriella; Wang, Eileen

- ACS Sustainable Chemistry & Engineering, Vol. 6, Issue 3

The Path Forward for Biofuels and Biomaterials

journal, January 2006

- Ragauskas, Arthur J.; Williams, Charlotte K.; Davison, Brian H.

- Science, Vol. 311, Issue 5760, p. 484-489

Mapping out the structural changes of natural and pretreated plant cell wall surfaces by atomic force microscopy single molecular recognition imaging

journal, January 2013

- Zhang, Mengmeng; Chen, Guojun; Kumar, Rajeev

- Biotechnology for Biofuels, Vol. 6, Issue 1

Features of promising technologies for pretreatment of lignocellulosic biomass

journal, April 2005

- Mosier, Nathan; Wyman, Charles; Dale, Bruce

- Bioresource Technology, Vol. 96, Issue 6, p. 673-686

Assessing the molecular structure basis for biomass recalcitrance during dilute acid and hydrothermal pretreatments

journal, January 2013

- Pu, Yunqiao; Hu, Fan; Huang, Fang

- Biotechnology for Biofuels, Vol. 6, Issue 1

Lignin transformations for high value applications: towards targeted modifications using green chemistry

journal, January 2017

- Gillet, S.; Aguedo, M.; Petitjean, L.

- Green Chemistry, Vol. 19, Issue 18

Recent updates on different methods of pretreatment of lignocellulosic feedstocks: a review

journal, January 2017

- Kumar, Adepu Kiran; Sharma, Shaishav

- Bioresources and Bioprocessing, Vol. 4, Issue 1

Characterization and analysis of the molecular weight of lignin for biorefining studies

journal, June 2014

- Tolbert, Allison; Akinosho, Hannah; Khunsupat, Ratayakorn

- Biofuels, Bioproducts and Biorefining, Vol. 8, Issue 6

Synthesis of tetrahydrofuran from maleic anhydride on Cu–ZnO–ZrO2/H-Y bifunctional catalysts

journal, July 2008

- Aghaziarati, Mahmoud; Soltanieh, Mohammad; Kazemeini, Mohammad

- Catalysis Communications, Vol. 9, Issue 13

Kinetics and Mechanism of Tetrahydrofuran Synthesis via 1,4-Butanediol Dehydration in High-Temperature Water

journal, August 2006

- Hunter, Shawn E.; Ehrenberger, Carolyn E.; Savage, Phillip E.

- The Journal of Organic Chemistry, Vol. 71, Issue 16

Hydrodeoxygenation of Furfural Over Supported Metal Catalysts: A Comparative Study of Cu, Pd and Ni

journal, March 2011

- Sitthisa, Surapas; Resasco, Daniel E.

- Catalysis Letters, Vol. 141, Issue 6

A review of the toxicological and environmental hazards and risks of tetrahydrofuran

journal, October 2013

- Fowles, Jefferson; Boatman, Rodney; Bootman, Jim

- Critical Reviews in Toxicology, Vol. 43, Issue 10

THF co-solvent enhances hydrocarbon fuel precursor yields from lignocellulosic biomass

journal, January 2013

- Cai, Charles M.; Zhang, Taiying; Kumar, Rajeev

- Green Chemistry, Vol. 15, Issue 11

Co-solvent Pretreatment Reduces Costly Enzyme Requirements for High Sugar and Ethanol Yields from Lignocellulosic Biomass

journal, February 2015

- Nguyen, Thanh Yen; Cai, Charles M.; Kumar, Rajeev

- ChemSusChem, Vol. 8, Issue 10

CELF pretreatment of corn stover boosts ethanol titers and yields from high solids SSF with low enzyme loadings

journal, January 2016

- Nguyen, Thanh Yen; Cai, Charles M.; Osman, Omar

- Green Chemistry, Vol. 18, Issue 6

Coupling metal halides with a co-solvent to produce furfural and 5-HMF at high yields directly from lignocellulosic biomass as an integrated biofuels strategy

journal, January 2014

- Cai, Charles M.; Nagane, Nikhil; Kumar, Rajeev

- Green Chem., Vol. 16, Issue 8

Overcoming factors limiting high-solids fermentation of lignocellulosic biomass to ethanol

journal, October 2017

- Nguyen, Thanh Yen; Cai, Charles M.; Kumar, Rajeev

- Proceedings of the National Academy of Sciences, Vol. 114, Issue 44

Deposition of Lignin Droplets Produced During Dilute Acid Pretreatment of Maize Stems Retards Enzymatic Hydrolysis of Cellulose

journal, December 2007

- Selig, M. J.; Viamajala, S.; Decker, S. R.

- Biotechnology Progress, Vol. 23, Issue 6

Investigation of lignin deposition on cellulose during hydrothermal pretreatment, its effect on cellulose hydrolysis, and underlying mechanisms: Investigation of Lignin Deposition on Cellulose

journal, October 2013

- Li, Hongjia; Pu, Yunqiao; Kumar, Rajeev

- Biotechnology and Bioengineering, Vol. 111, Issue 3

The lignin present in steam pretreated softwood binds enzymes and limits cellulose accessibility

journal, January 2012

- Kumar, Linoj; Arantes, Valdeir; Chandra, Richard

- Bioresource Technology, Vol. 103, Issue 1

Cosolvent pretreatment in cellulosic biofuel production: effect of tetrahydrofuran-water on lignin structure and dynamics

journal, January 2016

- Smith, Micholas Dean; Mostofian, Barmak; Cheng, Xiaolin

- Green Chemistry, Vol. 18, Issue 5

Enhanced sampling simulation analysis of the structure of lignin in the THF–water miscibility gap

journal, January 2016

- Smith, Micholas Dean; Petridis, Loukas; Cheng, Xiaolin

- Physical Chemistry Chemical Physics, Vol. 18, Issue 9

Adding tetrahydrofuran to dilute acid pretreatment provides new insights into substrate changes that greatly enhance biomass deconstruction by Clostridium thermocellum and fungal enzymes

journal, November 2017

- Thomas, Vanessa A.; Donohoe, Bryon S.; Li, Mi

- Biotechnology for Biofuels, Vol. 10, Issue 1

An In-Depth Understanding of Biomass Recalcitrance Using Natural Poplar Variants as the Feedstock

journal, December 2016

- Meng, Xianzhi; Pu, Yunqiao; Yoo, Chang Geun

- ChemSusChem, Vol. 10, Issue 1

Effect of in Vivo Deuteration on Structure of Switchgrass Lignin

journal, August 2017

- Meng, Xianzhi; Evans, Barbara R.; Yoo, Chang Geun

- ACS Sustainable Chemistry & Engineering, Vol. 5, Issue 9

Chemical Transformations of Buddleja davidii Lignin during Ethanol Organosolv Pretreatment

journal, April 2010

- Hallac, Bassem B.; Pu, Yunqiao; Ragauskas, Arthur J.

- Energy & Fuels, Vol. 24, Issue 4

Lignin Structural Modifications Resulting from Ethanol Organosolv Treatment of Loblolly Pine

journal, January 2010

- Sannigrahi, Poulomi; Ragauskas, Arthur J.; Miller, Stephen J.

- Energy & Fuels, Vol. 24, Issue 1, p. 683-689

Structural Characterization of Switchgrass Lignin after Ethanol Organosolv Pretreatment

journal, December 2011

- Hu, Gang; Cateto, Carolina; Pu, Yunqiao

- Energy & Fuels, Vol. 26, Issue 1

Characterization of milled wood lignin and ethanol organosolv lignin from miscanthus

journal, October 2009

- El Hage, Roland; Brosse, Nicolas; Chrusciel, Laurent

- Polymer Degradation and Stability, Vol. 94, Issue 10

Poplar as a feedstock for biofuels: A review of compositional characteristics

journal, March 2010

- Sannigrahi, Poulomi; Ragauskas, Arthur J.; Tuskan, Gerald A.

- Biofuels, Bioproducts and Biorefining, Vol. 4, Issue 2

Effects of organosolv and ammonia pretreatments on lignin properties and its inhibition for enzymatic hydrolysis

journal, January 2017

- Yoo, Chang Geun; Li, Mi; Meng, Xianzhi

- Green Chemistry, Vol. 19, Issue 8

Pretreatment of Lodgepole Pine Killed by Mountain Pine Beetle Using the Ethanol Organosolv Process: Fractionation and Process Optimization

journal, April 2007

- Pan, Xuejun; Xie, Dan; Yu, Richard W.

- Industrial & Engineering Chemistry Research, Vol. 46, Issue 8

Revealing the structure and distribution changes of Eucalyptus lignin during the hydrothermal and alkaline pretreatments

journal, April 2017

- Wang, Chenzhou; Li, Hanyin; Li, Mingfei

- Scientific Reports, Vol. 7, Issue 1

Acid Reactions of Lignin Models of β-5 Type

journal, January 1999

- Li, S.; Lundquist, K.

- Holzforschung, Vol. 53, Issue 1

Role of Functional Groups in Lignin Inhibition of Enzymatic Hydrolysis of Cellulose to Glucose

journal, March 2008

- Pan, Xuejun

- Journal of Biobased Materials and Bioenergy, Vol. 2, Issue 1

Bioconversion of hybrid poplar to ethanol and co-products using an organosolv fractionation process: Optimization of process yields

journal, January 2006

- Pan, Xuejun; Gilkes, Neil; Kadla, John

- Biotechnology and Bioengineering, Vol. 94, Issue 5, p. 851-861

Lignin and Its Applications with Polymers

journal, March 2009

- Satheesh Kumar, M. N.; Mohanty, A. K.; Erickson, L.

- Journal of Biobased Materials and Bioenergy, Vol. 3, Issue 1

Lignin Valorization: Improving Lignin Processing in the Biorefinery

journal, May 2014

- Ragauskas, A. J.; Beckham, G. T.; Biddy, M. J.

- Science, Vol. 344, Issue 6185, p. 1246843-1246843

NMR a critical tool to study the production of carbon fiber from lignin

journal, February 2013

- Foston, Marcus; Nunnery, Grady A.; Meng, Xianzhi

- Carbon, Vol. 52

Works referencing / citing this record:

Diol pretreatment to fractionate a reactive lignin in lignocellulosic biomass biorefineries

journal, January 2019

- Dong, Chengyu; Meng, Xianzhi; Yeung, Chi Shun

- Green Chemistry, Vol. 21, Issue 10

Performance of three delignifying pretreatments on hardwoods: hydrolysis yields, comprehensive mass balances, and lignin properties

journal, September 2019

- Bhalla, Aditya; Cai, Charles M.; Xu, Feng

- Biotechnology for Biofuels, Vol. 12, Issue 1

Determination of hydroxyl groups in biorefinery resources via quantitative 31P NMR spectroscopy

journal, August 2019

- Meng, Xianzhi; Crestini, Claudia; Ben, Haoxi

- Nature Protocols, Vol. 14, Issue 9

Lignin‐derived electrochemical energy materials and systems

journal, January 2020

- Wu, Xiaoyu; Jiang, Junhua; Wang, Chongmin

- Biofuels, Bioproducts and Biorefining, Vol. 14, Issue 3

A critical review on the analysis of lignin carbohydrate bonds

journal, January 2019

- Giummarella, Nicola; Pu, Yunqiao; Ragauskas, Arthur J.

- Green Chemistry, Vol. 21, Issue 7

Synthesis, Characterization, and Utilization of a Lignin-Based Adsorbent for Effective Removal of Azo Dye from Aqueous Solution

journal, February 2020

- Meng, Xianzhi; Scheidemantle, Brent; Li, Mi

- ACS Omega, Vol. 5, Issue 6

Figures / Tables found in this record:

Search WorldCat to find libraries that may hold this journal

Search WorldCat to find libraries that may hold this journal