Toward digitally controlled catalyst architectures: Hierarchical nanoporous gold via 3D printing

Abstract

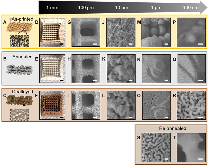

Monolithic nanoporous metals, derived from dealloying, have a unique bicontinuous solid/void structure that provides both large surface area and high electrical conductivity, making them ideal candidates for various energy applications. However, many of these applications would greatly benefit from the integration of an engineered hierarchical macroporous network structure that increases and directs mass transport. We report on 3D (three-dimensional)–printed hierarchical nanoporous gold (3DP-hnp-Au) with engineered nonrandom macroarchitectures by combining 3D printing and dealloying. The material exhibits three distinct structural length scales ranging from the digitally controlled macroporous network structure (10 to 1000 μm) to the nanoscale pore/ligament morphology (30 to 500 nm) controlled by dealloying. Supercapacitance, pressure drop, and catalysis measurements reveal that the 3D hierarchical nature of our printed nanoporous metals markedly improves mass transport and reaction rates for both liquids and gases. Our approach can be applied to a variety of alloy systems and has the potential to revolutionize the design of (electro-)chemical plants by changing the scaling relations between volume and catalyst surface area.

- Authors:

-

- Lawrence Livermore National Lab. (LLNL), Livermore, CA (United States)

- Harvard Univ., Cambridge, MA (United States)

- Publication Date:

- Research Org.:

- Energy Frontier Research Centers (EFRC) (United States). Integrated Mesoscale Architectures for Sustainable Catalysis (IMASC); Lawrence Livermore National Laboratory (LLNL), Livermore, CA (United States); Harvard Univ., Cambridge, MA (United States)

- Sponsoring Org.:

- USDOE Office of Science (SC), Basic Energy Sciences (BES); LLNL Laboratory Directed Research and Development (LDRD) Program

- OSTI Identifier:

- 1515346

- Report Number(s):

- LLNL-JRNL-772599

Journal ID: ISSN 2375-2548; 964041

- Grant/Contract Number:

- AC52-07NA27344; SC0012573

- Resource Type:

- Accepted Manuscript

- Journal Name:

- Science Advances

- Additional Journal Information:

- Journal Volume: 4; Journal Issue: 8; Journal ID: ISSN 2375-2548

- Publisher:

- AAAS

- Country of Publication:

- United States

- Language:

- English

- Subject:

- 36 MATERIALS SCIENCE

Citation Formats

Zhu, Cheng, Qi, Zhen, Beck, Victor A., Luneau, Mathilde, Lattimer, Judith, Chen, Wen, Worsley, Marcus A., Ye, Jianchao, Duoss, Eric B., Spadaccini, Christopher M., Friend, Cynthia M., and Biener, Juergen. Toward digitally controlled catalyst architectures: Hierarchical nanoporous gold via 3D printing. United States: N. p., 2018.

Web. doi:10.1126/sciadv.aas9459.

Zhu, Cheng, Qi, Zhen, Beck, Victor A., Luneau, Mathilde, Lattimer, Judith, Chen, Wen, Worsley, Marcus A., Ye, Jianchao, Duoss, Eric B., Spadaccini, Christopher M., Friend, Cynthia M., & Biener, Juergen. Toward digitally controlled catalyst architectures: Hierarchical nanoporous gold via 3D printing. United States. https://doi.org/10.1126/sciadv.aas9459

Zhu, Cheng, Qi, Zhen, Beck, Victor A., Luneau, Mathilde, Lattimer, Judith, Chen, Wen, Worsley, Marcus A., Ye, Jianchao, Duoss, Eric B., Spadaccini, Christopher M., Friend, Cynthia M., and Biener, Juergen. Fri .

"Toward digitally controlled catalyst architectures: Hierarchical nanoporous gold via 3D printing". United States. https://doi.org/10.1126/sciadv.aas9459. https://www.osti.gov/servlets/purl/1515346.

@article{osti_1515346,

title = {Toward digitally controlled catalyst architectures: Hierarchical nanoporous gold via 3D printing},

author = {Zhu, Cheng and Qi, Zhen and Beck, Victor A. and Luneau, Mathilde and Lattimer, Judith and Chen, Wen and Worsley, Marcus A. and Ye, Jianchao and Duoss, Eric B. and Spadaccini, Christopher M. and Friend, Cynthia M. and Biener, Juergen},

abstractNote = {Monolithic nanoporous metals, derived from dealloying, have a unique bicontinuous solid/void structure that provides both large surface area and high electrical conductivity, making them ideal candidates for various energy applications. However, many of these applications would greatly benefit from the integration of an engineered hierarchical macroporous network structure that increases and directs mass transport. We report on 3D (three-dimensional)–printed hierarchical nanoporous gold (3DP-hnp-Au) with engineered nonrandom macroarchitectures by combining 3D printing and dealloying. The material exhibits three distinct structural length scales ranging from the digitally controlled macroporous network structure (10 to 1000 μm) to the nanoscale pore/ligament morphology (30 to 500 nm) controlled by dealloying. Supercapacitance, pressure drop, and catalysis measurements reveal that the 3D hierarchical nature of our printed nanoporous metals markedly improves mass transport and reaction rates for both liquids and gases. Our approach can be applied to a variety of alloy systems and has the potential to revolutionize the design of (electro-)chemical plants by changing the scaling relations between volume and catalyst surface area.},

doi = {10.1126/sciadv.aas9459},

journal = {Science Advances},

number = 8,

volume = 4,

place = {United States},

year = {Fri Aug 31 00:00:00 EDT 2018},

month = {Fri Aug 31 00:00:00 EDT 2018}

}

Web of Science

Figures / Tables:

Fig. 1: 3D printed hierarchical nanoporous gold (3DP-hnp-Au) exhibits control over structure that spans over seven orders of magnitude in length scales, from centimeters to nanometers. A-C, Schematic illustrations of (A) 3D printing inks composed of mixtures of Au and Ag microparticles, polymer binder, and solvent (binder and solvent aremore »

Fig. 1: 3D printed hierarchical nanoporous gold (3DP-hnp-Au) exhibits control over structure that spans over seven orders of magnitude in length scales, from centimeters to nanometers. A-C, Schematic illustrations of (A) 3D printing inks composed of mixtures of Au and Ag microparticles, polymer binder, and solvent (binder and solvent aremore »

Works referenced in this record:

Dynamic restructuring drives catalytic activity on nanoporous gold–silver alloy catalysts

journal, December 2016

- Zugic, Branko; Wang, Lucun; Heine, Christian

- Nature Materials, Vol. 16, Issue 5

3D-Printing of Meso-structurally Ordered Carbon Fiber/Polymer Composites with Unprecedented Orthotropic Physical Properties

journal, March 2017

- Lewicki, James P.; Rodriguez, Jennifer N.; Zhu, Cheng

- Scientific Reports, Vol. 7, Issue 1

Evolution of nanoporosity in dealloying

journal, March 2001

- Erlebacher, Jonah; Aziz, Michael J.; Karma, Alain

- Nature, Vol. 410, Issue 6827, p. 450-453

Nanoporous Gold—Testing Macro-scale Samples to Probe Small-scale Mechanical Behavior

journal, September 2015

- Mameka, Nadiia; Wang, Ke; Markmann, Jürgen

- Materials Research Letters, Vol. 4, Issue 1

Direct metal writing: Controlling the rheology through microstructure

journal, February 2017

- Chen, Wen; Thornley, Luke; Coe, Hannah G.

- Applied Physics Letters, Vol. 110, Issue 9

Mapping reactive flow patterns in monolithic nanoporous catalysts

journal, July 2016

- Falcucci, Giacomo; Succi, Sauro; Montessori, Andrea

- Microfluidics and Nanofluidics, Vol. 20, Issue 7

Three-dimensional morphology of nanoporous gold

journal, June 2008

- Fujita, Takeshi; Qian, Li-Hua; Inoke, Koji

- Applied Physics Letters, Vol. 92, Issue 25, Article No. 251902

3D printed functional nanomaterials for electrochemical energy storage

journal, August 2017

- Zhu, Cheng; Liu, Tianyu; Qian, Fang

- Nano Today, Vol. 15

Ultra-strong and Low-Density Nanotubular Bulk Materials with Tunable Feature Sizes

journal, May 2014

- Biener, Monika M.; Ye, Jianchao; Baumann, Theodore F.

- Advanced Materials, Vol. 26, Issue 28

Thixotropic rheology of concentrated alumina colloidal gels for solid freeform fabrication

journal, May 2011

- Zhu, Cheng; Smay, James E.

- Journal of Rheology, Vol. 55, Issue 3

Nanoporous gold: a new material for catalytic and sensor applications

journal, January 2010

- Wittstock, Arne; Biener, Jürgen; Bäumer, Marcus

- Physical Chemistry Chemical Physics, Vol. 12, Issue 40

Omnidirectional Printing of Flexible, Stretchable, and Spanning Silver Microelectrodes

journal, March 2009

- Ahn, B. Y.; Duoss, E. B.; Motala, M. J.

- Science, Vol. 323, Issue 5921, p. 1590-1593

Direct Ink Writing of Three-Dimensional Ceramic Structures

journal, December 2006

- Lewis, Jennifer A.; Smay, James E.; Stuecker, John

- Journal of the American Ceramic Society, Vol. 89, Issue 12, p. 3599-3609

Nanoporous Gold Catalysts for Selective Gas-Phase Oxidative Coupling of Methanol at Low Temperature

journal, January 2010

- Wittstock, A.; Zielasek, V.; Biener, J.

- Science, Vol. 327, Issue 5963

Porous Gold with a Nested-Network Architecture and Ultrafine Structure

journal, March 2015

- Qi, Zhen; Vainio, Ulla; Kornowski, Andreas

- Advanced Functional Materials, Vol. 25, Issue 17

Nanoporous Gold: From an Ancient Technology to a High-Tech Material

book, January 2012

- Wittstock, Arne; Biener, Jürgen; Erlebacher, Jonah

- RSC Nanoscience & Nanotechnology, 264 p.

Nanoporous metals: fabrication strategies and advanced electrochemical applications in catalysis, sensing and energy systems

journal, January 2012

- Zhang, Jintao; Li, Chang Ming

- Chemical Society Reviews, Vol. 41, Issue 21

Supercapacitors Based on Three-Dimensional Hierarchical Graphene Aerogels with Periodic Macropores

journal, January 2016

- Zhu, Cheng; Liu, Tianyu; Qian, Fang

- Nano Letters, Vol. 16, Issue 6, p. 3448-3456

Controlling Material Reactivity Using Architecture

journal, December 2015

- Sullivan, Kyle T.; Zhu, Cheng; Duoss, Eric B.

- Advanced Materials, Vol. 28, Issue 10

Surface-chemistry-driven actuation in nanoporous gold

journal, November 2008

- Biener, J.; Wittstock, A.; Zepeda-Ruiz, L. A.

- Nature Materials, Vol. 8, Issue 1

3D-Printed Transparent Glass

journal, April 2017

- Nguyen, Du T.; Meyers, Cameron; Yee, Timothy D.

- Advanced Materials, Vol. 29, Issue 26

Hierarchical Nested-Network Nanostructure by Dealloying

journal, June 2013

- Qi, Zhen; Weissmüller, Jörg

- ACS Nano, Vol. 7, Issue 7

Gold Catalysts: Nanoporous Gold Foams

journal, December 2006

- Zielasek, Volkmar; Jürgens, Birte; Schulz, Christian

- Angewandte Chemie International Edition, Vol. 45, Issue 48

Self-Diffusion in Silver-Gold Solid Solutions

journal, January 1963

- Mallard, W. C.; Gardner, A. B.; Bass, Ralph F.

- Physical Review, Vol. 129, Issue 2

Nanoporous-gold-based composites: toward tensile ductility

journal, June 2015

- Wang, Ke; Kobler, Aaron; Kübel, Christian

- NPG Asia Materials, Vol. 7, Issue 6

Nanoporous Metals with Controlled Multimodal Pore Size Distribution

journal, July 2003

- Ding, Yi; Erlebacher, Jonah

- Journal of the American Chemical Society, Vol. 125, Issue 26

Size Effects on the Mechanical Behavior of Nanoporous Au

journal, October 2006

- Biener, Juergen; Hodge, Andrea M.; Hayes, Joel R.

- Nano Letters, Vol. 6, Issue 10

Synthesis and Characterization of Hierarchical Porous Gold Materials

journal, February 2007

- Nyce, Gregory W.; Hayes, Joel R.; Hamza, Alex V.

- Chemistry of Materials, Vol. 19, Issue 3

Principles and applications of electrochemical capacitors

journal, May 2000

- Kötz, R.; Carlen, M.

- Electrochimica Acta, Vol. 45, Issue 15-16

Surface area and pore size characteristics of nanoporous gold subjected to thermal, mechanical, or surface modification studied using gas adsorption isotherms, cyclic voltammetry, thermogravimetric analysis, and scanning electron microscopy

journal, January 2012

- Tan, Yih Horng; Davis, Jason A.; Fujikawa, Kohki

- Journal of Materials Chemistry, Vol. 22, Issue 14

Catenary shape evolution of spanning structures in direct-write assembly of colloidal gels

journal, March 2012

- Zhu, Cheng; Smay, James E.

- Journal of Materials Processing Technology, Vol. 212, Issue 3

Nanoporous Gold Leaf: ?Ancient Technology?/Advanced Material

journal, November 2004

- Ding, Y.; Kim, Y. -J.; Erlebacher, J.

- Advanced Materials, Vol. 16, Issue 21

Composites of Nanoporous Gold and Polymer

journal, January 2013

- Wang, Ke; Weissmüller, Jörg

- Advanced Materials, Vol. 25, Issue 9

Low Temperature CO Oxidation over Unsupported Nanoporous Gold

journal, January 2007

- Xu, Caixia; Su, Jixin; Xu, Xiaohong

- Journal of the American Chemical Society, Vol. 129, Issue 1, p. 42-43

Highly compressible 3D periodic graphene aerogel microlattices

journal, April 2015

- Zhu, Cheng; Han, T. Yong-Jin; Duoss, Eric B.

- Nature Communications, Vol. 6, Issue 1

3D stochastic bicontinuous microstructures: Generation, topology and elasticity

journal, May 2018

- Soyarslan, Celal; Bargmann, Swantje; Pradas, Marc

- Acta Materialia, Vol. 149

Nanoporous Gold: Understanding the Origin of the Reactivity of a 21st Century Catalyst Made by Pre-Columbian Technology

journal, September 2015

- Biener, Juergen; Biener, Monika M.; Madix, Robert J.

- ACS Catalysis, Vol. 5, Issue 11

Direct Ink Writing of 3D Functional Materials

journal, November 2006

- Lewis, J. A.

- Advanced Functional Materials, Vol. 16, Issue 17

Ozone-Activated Nanoporous Gold: A Stable and Storable Material for Catalytic Oxidation

journal, June 2015

- Personick, Michelle L.; Zugic, Branko; Biener, Monika M.

- ACS Catalysis, Vol. 5, Issue 7

Gold Catalysts: Nanoporous Gold Foams.

journal, March 2007

- Zielasek, Volkmar; Juergens, Birte; Schulz, Christian

- ChemInform, Vol. 38, Issue 12

Nanoporous-gold-based composites : toward tensile ductility

text, January 2015

- Wang, Ke; Kobler, Aaron; Kübel, Christian

- Macmillan Publishers Limited, part of Springer Nature

Nanoporous gold : testing macro-scale samples to probe small-scale mechanical behavior

text, January 2015

- Mameka, Nadiia; Wang, Ke; Markmann, Jürgen

- Taylor & Francis

Evolution of Nanoporosity in Dealloying

text, January 2001

- Erlebacher, Jonah; Aziz, Michael J.; Karma, Alain

- arXiv

Composites of Nanoporous Gold and Polymer

journal, January 2013

- Wang, Ke; Weissmüller, Jörg

- Advanced Materials, Vol. 25, Issue 9

Ultra-strong and Low-Density Nanotubular Bulk Materials with Tunable Feature Sizes

journal, May 2014

- Biener, Monika M.; Ye, Jianchao; Baumann, Theodore F.

- Advanced Materials, Vol. 26, Issue 28

Mapping reactive flow patterns in monolithic nanoporous catalysts

journal, July 2016

- Falcucci, Giacomo; Succi, Sauro; Montessori, Andrea

- Microfluidics and Nanofluidics, Vol. 20, Issue 7

Supercapacitors Based on Three-Dimensional Hierarchical Graphene Aerogels with Periodic Macropores

journal, January 2016

- Zhu, Cheng; Liu, Tianyu; Qian, Fang

- Nano Letters, Vol. 16, Issue 6, p. 3448-3456

Low Temperature CO Oxidation over Unsupported Nanoporous Gold

journal, January 2007

- Xu, Caixia; Su, Jixin; Xu, Xiaohong

- Journal of the American Chemical Society, Vol. 129, Issue 1, p. 42-43

Hierarchical Nested-Network Nanostructure by Dealloying

journal, June 2013

- Qi, Zhen; Weissmüller, Jörg

- ACS Nano, Vol. 7, Issue 7

Evolution of nanoporosity in dealloying

journal, March 2001

- Erlebacher, Jonah; Aziz, Michael J.; Karma, Alain

- Nature, Vol. 410, Issue 6827, p. 450-453

Highly compressible 3D periodic graphene aerogel microlattices

journal, April 2015

- Zhu, Cheng; Han, T. Yong-Jin; Duoss, Eric B.

- Nature Communications, Vol. 6, Issue 1

Dynamic restructuring drives catalytic activity on nanoporous gold–silver alloy catalysts

journal, December 2016

- Zugic, Branko; Wang, Lucun; Heine, Christian

- Nature Materials, Vol. 16, Issue 5

Nanoporous gold: a new material for catalytic and sensor applications

journal, January 2010

- Wittstock, Arne; Biener, Jürgen; Bäumer, Marcus

- Physical Chemistry Chemical Physics, Vol. 12, Issue 40

Surface area and pore size characteristics of nanoporous gold subjected to thermal, mechanical, or surface modification studied using gas adsorption isotherms, cyclic voltammetry, thermogravimetric analysis, and scanning electron microscopy

journal, January 2012

- Tan, Yih Horng; Davis, Jason A.; Fujikawa, Kohki

- Journal of Materials Chemistry, Vol. 22, Issue 14

Three-dimensional morphology of nanoporous gold

journal, June 2008

- Fujita, Takeshi; Qian, Li-Hua; Inoke, Koji

- Applied Physics Letters, Vol. 92, Issue 25, Article No. 251902

3D stochastic bicontinuous microstructures: generation, topology and elasticity

text, January 2018

- Soyarslan, Celal; Bargmann, Swantje; Pradas, Marc

- TUHH Universitätsbibliothek

Porous gold with a nested-network architecture and ultrafine structure

journalarticle, January 2015

- Qi, Zhen; Vainio, Ulla; Kornowski, Andreas

- Wiley-VCH

Works referencing / citing this record:

Engineering Self‐Supported Noble Metal Foams Toward Electrocatalysis and Beyond

journal, August 2019

- Du, Ran; Jin, Xinyi; Hübner, René

- Advanced Energy Materials, Vol. 10, Issue 11

Advanced Polymer Designs for Direct‐Ink‐Write 3D Printing

journal, July 2019

- Li, Longyu; Lin, Qianming; Tang, Miao

- Chemistry – A European Journal, Vol. 25, Issue 46

Hierarchical Nanoporous Copper Architectures via 3D Printing Technique for Highly Efficient Catalysts

journal, April 2019

- Zhang, Yongzheng; Sun, Xiaohao; Nomura, Naoyuki

- Small, Vol. 15, Issue 22

Quantification of porosity in extensively nanoporous thin films in contact with gases and liquids

journal, September 2019

- Shpigel, Netanel; Sigalov, Sergey; Malchik, Fyodor

- Nature Communications, Vol. 10, Issue 1

Chemistry from 3D printed objects

journal, April 2019

- Hartings, Matthew R.; Ahmed, Zeeshan

- Nature Reviews Chemistry, Vol. 3, Issue 5

Hierarchical nanoporous Pd 1 Ag 1 alloy enables efficient electrocatalytic nitrogen reduction under ambient conditions

journal, January 2019

- Pang, Fangjie; Wang, Fei; Yang, Liting

- Chemical Communications, Vol. 55, Issue 68

Nanoporous gold metamaterials for high sensitivity plasmonic sensing

journal, January 2019

- Garoli, Denis; Calandrini, Eugenio; Giovannini, Giorgia

- Nanoscale Horizons, Vol. 4, Issue 5

Stiff isotropic lattices beyond the Maxwell criterion

journal, September 2019

- Chen, Wen; Watts, Seth; Jackson, Julie A.

- Science Advances, Vol. 5, Issue 9

Quantification of porosity in extensively nanoporous thin films in contact with gases and liquids

journal, September 2019

- Shpigel, Netanel; Sigalov, Sergey; Malchik, Fyodor

- Nature Communications, Vol. 10, Issue 1

Stiff isotropic lattices beyond the Maxwell criterion

journal, September 2019

- Chen, Wen; Watts, Seth; Jackson, Julie A.

- Science Advances, Vol. 5, Issue 9

Figures / Tables found in this record:

Search WorldCat to find libraries that may hold this journal

Search WorldCat to find libraries that may hold this journal