Gas Ingress and Egress of MEMS Multi-Chip Modules and MEMS Devices

Abstract

Hermetic microcircuit packaging was the dominant method of protecting semiconductor devices in the 1960s and 1970s. After losing majority market sectors to plastic encapsulated microelectronics over the last a few decades, hermetic packaging remains the preferred method of protecting semiconductor devices for critical applications such as in military, space, and medical fields, where components and systems are required to serve for several decades. MEMS devices impose additional challenges to packaging by requiring specific internal cavity pressures to function properly or deliver the needed quality (Q) factors. In MEMS multichip modules, internal pressure requirement conflicts arise when different MEMS devices require different internal gases and pressures. The authors developed a closed-formed equation to model pressure changes of hermetic enclosures due to gas ingression. This article expands the authors mathematical model to calculate gas pressure of a MEMS multichip module package as well as those of MEMS devices inside the multichip module package. These equations are not only capable of calculating service lifetimes of MEMS devices and multi-chip modules but can also help develop MEMS device packaging strategies to extend the service life of MEMS multi-chip modules.

- Authors:

-

- Sandia National Lab. (SNL-NM), Albuquerque, NM (United States). Department of Microsystems Integration

- Publication Date:

- Research Org.:

- Sandia National Lab. (SNL-NM), Albuquerque, NM (United States)

- Sponsoring Org.:

- USDOE National Nuclear Security Administration (NNSA), Office of Defense Nuclear Security

- OSTI Identifier:

- 1670730

- Report Number(s):

- SAND-2019-9202J

Journal ID: ISSN 2327-2503; 678243

- Grant/Contract Number:

- AC04-94AL85000; NA0003525

- Resource Type:

- Accepted Manuscript

- Journal Name:

- Advances in Materials

- Additional Journal Information:

- Journal Volume: 8; Journal Issue: 4; Journal ID: ISSN 2327-2503

- Publisher:

- Science Publishing Group

- Country of Publication:

- United States

- Language:

- English

- Subject:

- 36 MATERIALS SCIENCE; gas leak; ingress; egress; hermetic package; MEMS; MCM; reliability

Citation Formats

Fang, Lu, and Alexander Menk, Lyle. Gas Ingress and Egress of MEMS Multi-Chip Modules and MEMS Devices. United States: N. p., 2019.

Web. doi:10.11648/j.am.20190804.17.

Fang, Lu, & Alexander Menk, Lyle. Gas Ingress and Egress of MEMS Multi-Chip Modules and MEMS Devices. United States. https://doi.org/10.11648/j.am.20190804.17

Fang, Lu, and Alexander Menk, Lyle. Fri .

"Gas Ingress and Egress of MEMS Multi-Chip Modules and MEMS Devices". United States. https://doi.org/10.11648/j.am.20190804.17. https://www.osti.gov/servlets/purl/1670730.

@article{osti_1670730,

title = {Gas Ingress and Egress of MEMS Multi-Chip Modules and MEMS Devices},

author = {Fang, Lu and Alexander Menk, Lyle},

abstractNote = {Hermetic microcircuit packaging was the dominant method of protecting semiconductor devices in the 1960s and 1970s. After losing majority market sectors to plastic encapsulated microelectronics over the last a few decades, hermetic packaging remains the preferred method of protecting semiconductor devices for critical applications such as in military, space, and medical fields, where components and systems are required to serve for several decades. MEMS devices impose additional challenges to packaging by requiring specific internal cavity pressures to function properly or deliver the needed quality (Q) factors. In MEMS multichip modules, internal pressure requirement conflicts arise when different MEMS devices require different internal gases and pressures. The authors developed a closed-formed equation to model pressure changes of hermetic enclosures due to gas ingression. This article expands the authors mathematical model to calculate gas pressure of a MEMS multichip module package as well as those of MEMS devices inside the multichip module package. These equations are not only capable of calculating service lifetimes of MEMS devices and multi-chip modules but can also help develop MEMS device packaging strategies to extend the service life of MEMS multi-chip modules.},

doi = {10.11648/j.am.20190804.17},

journal = {Advances in Materials},

number = 4,

volume = 8,

place = {United States},

year = {Fri Dec 13 00:00:00 EST 2019},

month = {Fri Dec 13 00:00:00 EST 2019}

}

Figures / Tables:

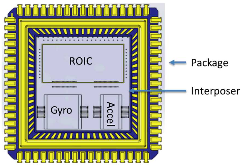

Figure 1: MEMS MCM floor plan

Figure 1: MEMS MCM floor plan

Figures / Tables found in this record:

Search WorldCat to find libraries that may hold this journal

Search WorldCat to find libraries that may hold this journal