A Reformulation of the Pseudo2D Battery Model Coupling Large Electrochemical-Mechanical Deformations at Particle and Electrode Levels

Abstract

The Pseudo2D electrochemical reaction/transport battery model is consistently reformulated based on the finite strain theory to incorporate the coupled effects of large electrochemical-mechanical deformations at both particle and electrode levels. The active material volume change due to lithium insertion/extraction causes the electrode deformation and porosity variation. The porosity variation affects the mechanical properties of each component of the cell as well as the transport processes. Consecutively, the electrode deformation also affects porosity variation and the electrochemical processes (transport and equilibrium potential). Variables such as particle size and specific surface area are also simultaneous updated based on the approximated electrode deformation and porosity distributions. The model is applied to simulate the performance of a cell composed of Si anode and NMC532 cathode to study the effect of active material volume change on the cell performances. The simulation results show that during the charging process the porosity of each cell component experiences significant reduction due to the large expansion of Si particles. Also, a notable hydrostatic stress develops within the cell, which introduces an overpotential in addition to that caused by porosity reduction. The model is also employed to study the effects of charging rate, initial anode porosity, cell loading and fixturemore »

- Authors:

- Publication Date:

- Research Org.:

- National Renewable Energy Laboratory (NREL), Golden, CO (United States)

- Sponsoring Org.:

- USDOE Office of Energy Efficiency and Renewable Energy (EERE), Office of Sustainable Transportation. Vehicle Technologies Office (VTO); USDOE Office of Energy Efficiency and Renewable Energy (EERE), Vehicle Technologies Office (EE-3V)

- OSTI Identifier:

- 1508204

- Alternate Identifier(s):

- OSTI ID: 1514838

- Report Number(s):

- NREL/JA-5400-73221

Journal ID: ISSN 0013-4651; /jes/166/8/A1330.atom

- Grant/Contract Number:

- AC36-08GO28308

- Resource Type:

- Published Article

- Journal Name:

- Journal of the Electrochemical Society

- Additional Journal Information:

- Journal Name: Journal of the Electrochemical Society Journal Volume: 166 Journal Issue: 8; Journal ID: ISSN 0013-4651

- Publisher:

- The Electrochemical Society

- Country of Publication:

- United States

- Language:

- English

- Subject:

- 25 ENERGY STORAGE; 33 ADVANCED PROPULSION SYSTEMS; silicon anode; large deformation; porosity variation; multi-scale deformation coupling

Citation Formats

Mai, Weijie, Colclasure, Andrew, and Smith, Kandler. A Reformulation of the Pseudo2D Battery Model Coupling Large Electrochemical-Mechanical Deformations at Particle and Electrode Levels. United States: N. p., 2019.

Web. doi:10.1149/2.0101908jes.

Mai, Weijie, Colclasure, Andrew, & Smith, Kandler. A Reformulation of the Pseudo2D Battery Model Coupling Large Electrochemical-Mechanical Deformations at Particle and Electrode Levels. United States. https://doi.org/10.1149/2.0101908jes

Mai, Weijie, Colclasure, Andrew, and Smith, Kandler. Mon .

"A Reformulation of the Pseudo2D Battery Model Coupling Large Electrochemical-Mechanical Deformations at Particle and Electrode Levels". United States. https://doi.org/10.1149/2.0101908jes.

@article{osti_1508204,

title = {A Reformulation of the Pseudo2D Battery Model Coupling Large Electrochemical-Mechanical Deformations at Particle and Electrode Levels},

author = {Mai, Weijie and Colclasure, Andrew and Smith, Kandler},

abstractNote = {The Pseudo2D electrochemical reaction/transport battery model is consistently reformulated based on the finite strain theory to incorporate the coupled effects of large electrochemical-mechanical deformations at both particle and electrode levels. The active material volume change due to lithium insertion/extraction causes the electrode deformation and porosity variation. The porosity variation affects the mechanical properties of each component of the cell as well as the transport processes. Consecutively, the electrode deformation also affects porosity variation and the electrochemical processes (transport and equilibrium potential). Variables such as particle size and specific surface area are also simultaneous updated based on the approximated electrode deformation and porosity distributions. The model is applied to simulate the performance of a cell composed of Si anode and NMC532 cathode to study the effect of active material volume change on the cell performances. The simulation results show that during the charging process the porosity of each cell component experiences significant reduction due to the large expansion of Si particles. Also, a notable hydrostatic stress develops within the cell, which introduces an overpotential in addition to that caused by porosity reduction. The model is also employed to study the effects of charging rate, initial anode porosity, cell loading and fixture condition.},

doi = {10.1149/2.0101908jes},

journal = {Journal of the Electrochemical Society},

number = 8,

volume = 166,

place = {United States},

year = {Mon Apr 22 00:00:00 EDT 2019},

month = {Mon Apr 22 00:00:00 EDT 2019}

}

https://doi.org/10.1149/2.0101908jes

Web of Science

Figures / Tables:

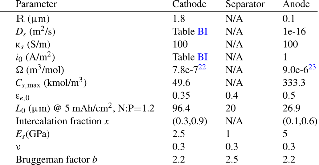

Table I: Values of the parameters used in the current model for all example problems unless stated otherwise.

Table I: Values of the parameters used in the current model for all example problems unless stated otherwise.

Works referenced in this record:

A battery model that fully couples mechanics and electrochemistry at both particle and electrode levels by incorporation of particle interaction

journal, August 2017

- Wu, Bin; Lu, Wei

- Journal of Power Sources, Vol. 360

A finite deformation stress-dependent chemical potential and its applications to lithium ion batteries

journal, July 2012

- Cui, Zhiwei; Gao, Feng; Qu, Jianmin

- Journal of the Mechanics and Physics of Solids, Vol. 60, Issue 7

Effect of Porosity on the Capacity Fade of a Lithium-Ion Battery

journal, January 2004

- Sikha, Godfrey; Popov, Branko N.; White, Ralph E.

- Journal of The Electrochemical Society, Vol. 151, Issue 7

Comparison of Modeling Predictions with Experimental Data from Plastic Lithium Ion Cells

journal, January 1996

- Doyle, Marc

- Journal of The Electrochemical Society, Vol. 143, Issue 6

Simulation and Optimization of the Dual Lithium Ion Insertion Cell

journal, January 1994

- Fuller, Thomas F.

- Journal of The Electrochemical Society, Vol. 141, Issue 1

Colossal Reversible Volume Changes in Lithium Alloys

journal, January 2001

- Beaulieu, L. Y.; Eberman, K. W.; Turner, R. L.

- Electrochemical and Solid-State Letters, Vol. 4, Issue 9

Computational analysis of chemomechanical behaviors of composite electrodes in Li-ion batteries

journal, August 2016

- Xu, Rong; Scalco de Vasconcelos, Luize; Zhao, Kejie

- Journal of Materials Research, Vol. 31, Issue 18

Modeling Volume Changes in Porous Electrodes

journal, January 2006

- Gomadam, Parthasarathy M.; Weidner, John W.

- Journal of The Electrochemical Society, Vol. 153, Issue 1

Modeling Battery Performance Due to Intercalation Driven Volume Change in Porous Electrodes

journal, January 2017

- Garrick, Taylor R.; Higa, Kenneth; Wu, Shao-Ling

- Journal of The Electrochemical Society, Vol. 164, Issue 11

Modeling Volume Change in Dual Insertion Electrodes

journal, January 2017

- Garrick, Taylor R.; Huang, Xinyu; Srinivasan, Venkat

- Journal of The Electrochemical Society, Vol. 164, Issue 11

A review of the electrochemical performance of alloy anodes for lithium-ion batteries

journal, January 2011

- Zhang, Wei-Jun

- Journal of Power Sources, Vol. 196, Issue 1

Voltage hysteresis of lithium ion batteries caused by mechanical stress

journal, January 2016

- Lu, Bo; Song, Yicheng; Zhang, Qinglin

- Physical Chemistry Chemical Physics, Vol. 18, Issue 6

Volume, Pressure and Thickness Evolution of Li-Ion Pouch Cells with Silicon-Composite Negative Electrodes

journal, January 2017

- Louli, A. J.; Li, Jing; Trussler, S.

- Journal of The Electrochemical Society, Vol. 164, Issue 12

Stress generation and fracture in lithium insertion materials

journal, March 2006

- Christensen, John; Newman, John

- Journal of Solid State Electrochemistry, Vol. 10, Issue 5

Large Plastic Deformation in High-Capacity Lithium-Ion Batteries Caused by Charge and Discharge: Large Plastic Deformation in Lithium-Ion Batteries

journal, March 2011

- Zhao, Kejie; Pharr, Matt; Cai, Shengqiang

- Journal of the American Ceramic Society, Vol. 94

A review on the key issues for lithium-ion battery management in electric vehicles

journal, March 2013

- Lu, Languang; Han, Xuebing; Li, Jianqiu

- Journal of Power Sources, Vol. 226, p. 272-288

Analysis of a Lithium/Thionyl Chloride Battery under Moderate-Rate Discharge

journal, January 1999

- Jain, Mukul

- Journal of The Electrochemical Society, Vol. 146, Issue 11

Evolution of stress within a spherical insertion electrode particle under potentiostatic and galvanostatic operation

journal, May 2009

- Cheng, Yang-Tse; Verbrugge, Mark W.

- Journal of Power Sources, Vol. 190, Issue 2, p. 453-460

Intercalation-Induced Stress and Heat Generation within Single Lithium-Ion Battery Cathode Particles

journal, January 2008

- Zhang, Xiangchun; Sastry, Ann Marie; Shyy, Wei

- Journal of The Electrochemical Society, Vol. 155, Issue 7

Investigation of the chemo-mechanical coupling in lithiation/delithiation of amorphous Si through simulations of Si thin films and Si nanospheres

journal, September 2016

- Wang, Miao; Xiao, Xinran

- Journal of Power Sources, Vol. 326

Alloy Design for Lithium-Ion Battery Anodes

journal, January 2007

- Obrovac, M. N.; Christensen, Leif; Le, Dinh Ba

- Journal of The Electrochemical Society, Vol. 154, Issue 9, p. A849-A855

Figures / Tables found in this record:

Search WorldCat to find libraries that may hold this journal

Search WorldCat to find libraries that may hold this journal