Microstructure and mechanical properties of FeCrAl alloys under heavy ion irradiations

Abstract

FeCrAl ferritic alloys are excellent cladding candidates for accident tolerant fuel systems due to their high resistance to oxidation as a result of formation of a protective Al2O3 scale at high temperatures in steam. In this study, we report the irradiation response of the 10Cr and 13Cr FeCrAl cladding tubes under Fe2+ ion irradiation up to ~16 dpa at 300 °C. Dislocation loop size, density and characteristics were determined using both two beam bright field transmission electron microscopy and on-zone scanning transmission electron microscopy techniques. 10Cr (C06M2) tube has a lower dislocation density, larger grain size and a slightly weaker texture compared to the 13Cr (C36M3) tube before irradiation. After irradiation to 0.7 dpa and 16 dpa, the fraction of <100> type sessile dislocations decreases with increasing Cr amount in the alloys. It has been found that there is neither void formation nor α' precipitation as a result of ion irradiations in either alloy. Therefore, dislocation loops were determined to be the only irradiation induced defects contributing to the hardening. Nanoindentation testing before the irradiation revealed that the average nanohardness of the C36M3 tube is higher than that of the C06M2 tube. The average nanohardness of irradiated tube samples saturatedmore »

- Authors:

-

- Los Alamos National Lab. (LANL), Los Alamos, NM (United States)

- Publication Date:

- Research Org.:

- Los Alamos National Lab. (LANL), Los Alamos, NM (United States)

- Sponsoring Org.:

- USDOE Office of Nuclear Energy (NE); USDOE National Nuclear Security Administration (NNSA)

- OSTI Identifier:

- 1425772

- Alternate Identifier(s):

- OSTI ID: 1548647

- Report Number(s):

- LA-UR-18-20922

Journal ID: ISSN 0022-3115; TRN: US1802164

- Grant/Contract Number:

- AC52-06NA25396

- Resource Type:

- Accepted Manuscript

- Journal Name:

- Journal of Nuclear Materials

- Additional Journal Information:

- Journal Volume: 503; Journal Issue: C; Journal ID: ISSN 0022-3115

- Publisher:

- Elsevier

- Country of Publication:

- United States

- Language:

- English

- Subject:

- 36 MATERIALS SCIENCE

Citation Formats

Aydogan, E., Weaver, J. S., Maloy, S. A., El-Atwani, O., Wang, Y. Q., and Mara, N. A. Microstructure and mechanical properties of FeCrAl alloys under heavy ion irradiations. United States: N. p., 2018.

Web. doi:10.1016/j.jnucmat.2018.03.002.

Aydogan, E., Weaver, J. S., Maloy, S. A., El-Atwani, O., Wang, Y. Q., & Mara, N. A. Microstructure and mechanical properties of FeCrAl alloys under heavy ion irradiations. United States. https://doi.org/10.1016/j.jnucmat.2018.03.002

Aydogan, E., Weaver, J. S., Maloy, S. A., El-Atwani, O., Wang, Y. Q., and Mara, N. A. Fri .

"Microstructure and mechanical properties of FeCrAl alloys under heavy ion irradiations". United States. https://doi.org/10.1016/j.jnucmat.2018.03.002. https://www.osti.gov/servlets/purl/1425772.

@article{osti_1425772,

title = {Microstructure and mechanical properties of FeCrAl alloys under heavy ion irradiations},

author = {Aydogan, E. and Weaver, J. S. and Maloy, S. A. and El-Atwani, O. and Wang, Y. Q. and Mara, N. A.},

abstractNote = {FeCrAl ferritic alloys are excellent cladding candidates for accident tolerant fuel systems due to their high resistance to oxidation as a result of formation of a protective Al2O3 scale at high temperatures in steam. In this study, we report the irradiation response of the 10Cr and 13Cr FeCrAl cladding tubes under Fe2+ ion irradiation up to ~16 dpa at 300 °C. Dislocation loop size, density and characteristics were determined using both two beam bright field transmission electron microscopy and on-zone scanning transmission electron microscopy techniques. 10Cr (C06M2) tube has a lower dislocation density, larger grain size and a slightly weaker texture compared to the 13Cr (C36M3) tube before irradiation. After irradiation to 0.7 dpa and 16 dpa, the fraction of <100> type sessile dislocations decreases with increasing Cr amount in the alloys. It has been found that there is neither void formation nor α' precipitation as a result of ion irradiations in either alloy. Therefore, dislocation loops were determined to be the only irradiation induced defects contributing to the hardening. Nanoindentation testing before the irradiation revealed that the average nanohardness of the C36M3 tube is higher than that of the C06M2 tube. The average nanohardness of irradiated tube samples saturated at 1.6-2.0 GPa hardening for both tubes between ~3.4 dpa and ~16 dpa. The hardening calculated based on transmission electron microscopy was found to be consistent with nanohardness measurements.},

doi = {10.1016/j.jnucmat.2018.03.002},

journal = {Journal of Nuclear Materials},

number = C,

volume = 503,

place = {United States},

year = {Fri Mar 02 00:00:00 EST 2018},

month = {Fri Mar 02 00:00:00 EST 2018}

}

Web of Science

Figures / Tables:

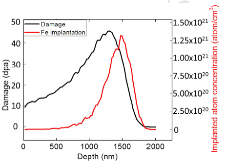

Fig. 1: SRIM calculated damage and implanted atom profiles for 45 peak dpa with 5 MeV Fe2+ ions using Kinchin-Pease option at 40 eV displacement energy.

Fig. 1: SRIM calculated damage and implanted atom profiles for 45 peak dpa with 5 MeV Fe2+ ions using Kinchin-Pease option at 40 eV displacement energy.

Works referenced in this record:

Advanced oxidation-resistant iron-based alloys for LWR fuel cladding

journal, May 2014

- Terrani, K. A.; Zinkle, S. J.; Snead, L. L.

- Journal of Nuclear Materials, Vol. 448, Issue 1-3

Alumina Scale Formation on a Powder Metallurgical FeCrAl Alloy (Kanthal APMT) at 900–1,100 °C in Dry O2 and in O2 + H2O

journal, September 2009

- Engkvist, J.; Canovic, S.; Hellström, K.

- Oxidation of Metals, Vol. 73, Issue 1-2

Development and property evaluation of nuclear grade wrought FeCrAl fuel cladding for light water reactors

journal, December 2015

- Yamamoto, Y.; Pint, B. A.; Terrani, K. A.

- Journal of Nuclear Materials, Vol. 467

Neutronic analysis of candidate accident-tolerant cladding concepts in pressurized water reactors

journal, January 2015

- George, Nathan Michael; Terrani, Kurt; Powers, Jeff

- Annals of Nuclear Energy, Vol. 75

Deformation behaviour of iron-rich iron-aluminum alloys at low temperatures

journal, June 2003

- Herrmann, J.; Inden, G.; Sauthoff, G.

- Acta Materialia, Vol. 51, Issue 10

The effect of heat treatment on recrystallized microstructure, precipitation and ductility of hot-rolled Fe–Cr–Al–REM ferritic stainless steel sheets

journal, February 2013

- Qu, H. P.; Lang, Y. P.; Yao, C. F.

- Materials Science and Engineering: A, Vol. 562

Microstructural stability of Fe–Cr–Al alloys at 450–550 °C

journal, February 2015

- Ejenstam, Jesper; Thuvander, Mattias; Olsson, Pär

- Journal of Nuclear Materials, Vol. 457

Mapping of 475°C embrittlement in ferritic Fe–Cr–Al alloys

journal, November 2010

- Kobayashi, Satoru; Takasugi, Takayuki

- Scripta Materialia, Vol. 63, Issue 11

Phase separation in PM 2000™ Fe-base ODS alloy: Experimental study at the atomic level

journal, August 2008

- Capdevila, C.; Miller, M. K.; Russell, K. F.

- Materials Science and Engineering: A, Vol. 490, Issue 1-2

Effect of α–α′ phase separation on notch impact behavior of oxide dispersion strengthened (ODS) Fe20Cr5Al alloy

journal, January 2014

- Chao, J.; Capdevila, C.; Serrano, M.

- Materials & Design, Vol. 53

On the α–α′ miscibility gap of Fe–Cr alloys

journal, December 2008

- Bonny, G.; Terentyev, D.; Malerba, L.

- Scripta Materialia, Vol. 59, Issue 11

A SANS investigation of the irradiation-enhanced α–α′ phases separation in 7–12 Cr martensitic steels

journal, February 2003

- Mathon, M. H.; de Carlan, Y.; Geoffroy, G.

- Journal of Nuclear Materials, Vol. 312, Issue 2-3

Irradiation-enhanced α′ precipitation in model FeCrAl alloys

journal, April 2016

- Edmondson, P. D.; Briggs, S. A.

- Scripta Materialia, Vol. 116

Dislocation loop formation in model FeCrAl alloys after neutron irradiation below 1 dpa

journal, November 2017

- Field, Kevin G.; Briggs, Samuel A.; Sridharan, Kumar

- Journal of Nuclear Materials, Vol. 495

Radiation tolerance of neutron-irradiated model Fe–Cr–Al alloys

journal, October 2015

- Field, Kevin G.; Hu, Xunxiang; Littrell, Kenneth C.

- Journal of Nuclear Materials, Vol. 465

Precipitation of α′ in neutron irradiated commercial FeCrAl alloys

journal, January 2018

- Field, Kevin G.; Littrell, Kenneth C.; Briggs, Samuel A.

- Scripta Materialia, Vol. 142

A combined APT and SANS investigation of α′ phase precipitation in neutron-irradiated model FeCrAl alloys

journal, May 2017

- Briggs, Samuel A.; Edmondson, Philip D.; Littrell, Kenneth C.

- Acta Materialia, Vol. 129

Challenges to the use of ion irradiation for emulating reactor irradiation

journal, April 2015

- Was, Gary S.

- Journal of Materials Research, Vol. 30, Issue 9

Opportunities and limitations for ion beams in radiation effects studies: Bridging critical gaps between charged particle and neutron irradiations

journal, January 2018

- Zinkle, S. J.; Snead, L. L.

- Scripta Materialia, Vol. 143

Synergistic effect of helium and hydrogen for defect evolution under multi-ion irradiation of Fe–Cr ferritic alloys

journal, August 2004

- Tanaka, T.; Oka, K.; Ohnuki, S.

- Journal of Nuclear Materials, Vol. 329-333

On the use of SRIM for computing radiation damage exposure

journal, September 2013

- Stoller, R. E.; Toloczko, M. B.; Was, G. S.

- Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, Vol. 310

A review of nanoindentation continuous stiffness measurement technique and its applications

journal, February 2002

- Li, Xiaodong; Bhushan, Bharat

- Materials Characterization, Vol. 48, Issue 1

Continuous Stiffness Measurement During Instrumented Indentation Testing

journal, January 2010

- Hay, J.; Agee, P.; Herbert, E.

- Experimental Techniques, Vol. 34, Issue 3

Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology

journal, January 2004

- Oliver, W. C.; Pharr, G. M.

- Journal of Materials Research, Vol. 19, Issue 1

Effect of self-ion irradiation on the microstructural changes of alloy EK-181 in annealed and severely deformed conditions

journal, April 2017

- Aydogan, E.; Chen, T.; Gigax, J. G.

- Journal of Nuclear Materials, Vol. 487

Effect of tube processing methods on microstructure, mechanical properties and irradiation response of 14YWT nanostructured ferritic alloys

journal, August 2017

- Aydogan, E.; Maloy, S. A.; Anderoglu, O.

- Acta Materialia, Vol. 134

Comparison of preparation techniques for nuclear materials for transmission electron microscopy (TEM)

journal, April 2015

- Aitkaliyeva, Assel; Madden, James W.; Miller, Brandon D.

- Journal of Nuclear Materials, Vol. 459

EELS log-ratio technique for specimen-thickness measurement in the TEM

journal, February 1988

- Malis, T.; Cheng, S. C.; Egerton, R. F.

- Journal of Electron Microscopy Technique, Vol. 8, Issue 2

Effect of shock loading on the microstructure, mechanical properties and grain boundary characteristics of HT-9 ferritic/martensitic steels

journal, January 2016

- Aydogan, E.; Anderoglu, O.; Maloy, S. A.

- Materials Science and Engineering: A, Vol. 651

Microstructure examination of Fe–14Cr ODS ferritic steels produced through different processing routes

journal, August 2014

- Oksiuta, Z.; Hosemann, P.; Vogel, S. C.

- Journal of Nuclear Materials, Vol. 451, Issue 1-3

Texture evolution in pure aluminum subjected to monotonous and reversal straining in high-pressure torsion

journal, May 2009

- Orlov, Dmitry; Bhattacharjee, Pinaki Prasad; Todaka, Yoshikazu

- Scripta Materialia, Vol. 60, Issue 10

Effect of tube processing methods on the texture and grain boundary characteristics of 14YWT nanostructured ferritic alloys

journal, April 2016

- Aydogan, E.; Pal, S.; Anderoglu, O.

- Materials Science and Engineering: A, Vol. 661

TEM characterization of dislocation loops in irradiated bcc Fe-based steels

journal, March 2013

- Yao, B.; Edwards, D. J.; Kurtz, R. J.

- Journal of Nuclear Materials, Vol. 434, Issue 1-3

-Loop characterization in α-Fe: comparison between experiments and modeling

journal, December 2002

- Marian, J.; Wirth, B. D.; Schäublin, R.

- Journal of Nuclear Materials, Vol. 307-311

Dislocation loops and bubbles in oxide dispersion strengthened ferritic steel after helium implantation under stress

journal, January 2008

- Chen, J.; Jung, P.; Hoffelner, W.

- Acta Materialia, Vol. 56, Issue 2

An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments

journal, June 1992

- Oliver, W. C.; Pharr, G. M.

- Journal of Materials Research, Vol. 7, Issue 06, p. 1564-1583

Understanding the effects of ion irradiation using nanoindentation techniques

journal, July 2015

- Hardie, Christopher D.; Roberts, Steve G.; Bushby, Andy J.

- Journal of Nuclear Materials, Vol. 462

Nanoindentation of model Fe–Cr alloys with self-ion irradiation

journal, February 2013

- Hardie, Christopher D.; Roberts, Steve G.

- Journal of Nuclear Materials, Vol. 433, Issue 1-3

A model of size effects in nano-indentation

journal, August 2006

- Huang, Y.; Zhang, F.; Hwang, K.

- Journal of the Mechanics and Physics of Solids, Vol. 54, Issue 8

The correlation of the indentation size effect measured with indenters of various shapes

journal, April 2002

- Swadener, J. G.; George, E. P.; Pharr, G. M.

- Journal of the Mechanics and Physics of Solids, Vol. 50, Issue 4

Indentation size effects in crystalline materials: A law for strain gradient plasticity

journal, March 1998

- Nix, William D.; Gao, Huajian

- Journal of the Mechanics and Physics of Solids, Vol. 46, Issue 3

The Indentation Size Effect: A Critical Examination of Experimental Observations and Mechanistic Interpretations

journal, June 2010

- Pharr, George M.; Herbert, Erik G.; Gao, Yanfei

- Annual Review of Materials Research, Vol. 40, Issue 1

Influences of pileup on the measurement of mechanical properties by load and depth sensing indentation techniques

journal, April 1998

- Bolshakov, A.; Pharr, G. M.

- Journal of Materials Research, Vol. 13, Issue 4

Effect of the Phase Transition on the Stability of Dislocation Loops in bcc Iron

journal, April 2008

- Dudarev, S. L.; Bullough, R.; Derlet, P. M.

- Physical Review Letters, Vol. 100, Issue 13

The temperature dependence of heavy-ion damage in iron: A microstructural transition at elevated temperatures

journal, December 2010

- Yao, Z.; Jenkins, M. L.; Hernández-Mayoral, M.

- Philosophical Magazine, Vol. 90, Issue 35-36

Dynamic observations of heavy-ion damage in Fe and Fe–Cr alloys

journal, May 2009

- Jenkins, M. L.; Yao, Z.; Hernández-Mayoral, M.

- Journal of Nuclear Materials, Vol. 389, Issue 2

Dislocation loop evolution during in-situ ion irradiation of model FeCrAl alloys

journal, September 2017

- Haley, Jack C.; Briggs, Samuel A.; Edmondson, Philip D.

- Acta Materialia, Vol. 136

Effects of alloying elements (Mo, Si) in an austenitic stainless steel on dislocation loop nucleation under ion irradiation

journal, December 1993

- Shigenaka, Naoto; Hashimoto, Tsuneyuki; Fuse, Motomasa

- Journal of Nuclear Materials, Vol. 207

Depth distribution of Frank loop defects formed in ion-irradiated stainless steel and its dependence on Si addition

journal, December 2015

- Chen, Dongyue; Murakami, Kenta; Dohi, Kenji

- Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, Vol. 365

Segregation behavior in proton- and heavy-ion-irradiated ferritic–martensitic alloys

journal, June 2011

- Jiao, Z.; Was, G. S.

- Acta Materialia, Vol. 59, Issue 11

Cr segregation on dislocation loops enhances hardening in ferritic Fe–Cr alloys

journal, March 2013

- Terentyev, D.; Bergner, F.; Osetsky, Y.

- Acta Materialia, Vol. 61, Issue 5

Modelling the diffusion of self-interstitial atom clusters in Fe-Cr alloys

journal, January 2008

- Terentyev, D.; Malerba, L.; Barashev, A. V.

- Philosophical Magazine, Vol. 88, Issue 1

Heavy-ion irradiations of Fe and Fe–Cr model alloys Part 1: Damage evolution in thin-foils at lower doses

journal, July 2008

- Yao, Z.; Hernández-Mayoral, M.; Jenkins, M. L.

- Philosophical Magazine, Vol. 88, Issue 21

Mechanism of Formation and Growth of Interstitial Loops in Ferritic Materials

journal, June 2002

- Marian, Jaime; Wirth, Brian D.; Perlado, J. Manuel

- Physical Review Letters, Vol. 88, Issue 25

Direct observation of the coalescence process between nanoscale dislocation loops with different Burgers vectors

journal, January 2011

- Arakawa, K.; Amino, T.; Mori, H.

- Acta Materialia, Vol. 59, Issue 1

Theory of transitions in dose dependence of radiation effects in structural alloys

journal, November 1993

- Mansur, L. K.

- Journal of Nuclear Materials, Vol. 206, Issue 2-3

Correlation of neutron and heavy-ion damage

journal, November 1978

- Mansur, L. K.

- Journal of Nuclear Materials, Vol. 78, Issue 1

Mechanical properties of neutron-irradiated model and commercial FeCrAl alloys

journal, June 2017

- Field, Kevin G.; Briggs, Samuel A.; Sridharan, Kumar

- Journal of Nuclear Materials, Vol. 489

Mechanical Performance of Ferritic Martensitic Steels for High Dose Applications in Advanced Nuclear Reactors

journal, December 2012

- Anderoglu, Osman; Byun, Thak Sang; Toloczko, Mychailo

- Metallurgical and Materials Transactions A, Vol. 44, Issue S1

The evolution of mechanical property change in irradiated austenitic stainless steels

journal, November 1993

- Lucas, G. E.

- Journal of Nuclear Materials, Vol. 206, Issue 2-3

On the relationship between uniaxial yield strength and resolved shear stress in polycrystalline materials

journal, December 2000

- Stoller, R. E.; Zinkle, S. J.

- Journal of Nuclear Materials, Vol. 283-287

Modeling the microstructure–mechanical property relationship for a 12Cr–2W–V–Mo–Ni power plant steel

journal, November 2003

- Li, Q.

- Materials Science and Engineering A, Vol. 361, Issue 1-2

The relationship between hardness and yield stress in irradiated austenitic and ferritic steels

journal, February 2005

- Busby, Jeremy T.; Hash, Mark C.; Was, Gary S.

- Journal of Nuclear Materials, Vol. 336, Issue 2-3

Low-activation ferritic and martensitic steels for fusion application

journal, October 1996

- Kohyama, A.; Hishinuma, A.; Gelles, D. S.

- Journal of Nuclear Materials, Vol. 233-237

Effect of Cr on the mechanical properties and microstructure of Fe–Cr model alloys after n-irradiation

journal, June 2008

- Matijasevic, M.; Almazouzi, A.

- Journal of Nuclear Materials, Vol. 377, Issue 1

Phase stability of an HT-9 duct irradiated in FFTF

journal, November 2012

- Anderoglu, O.; Van den Bosch, J.; Hosemann, P.

- Journal of Nuclear Materials, Vol. 430, Issue 1-3

α′ precipitation in neutron-irradiated Fe–Cr alloys

journal, March 2014

- Bachhav, Mukesh; Robert Odette, G.; Marquis, Emmanuelle A.

- Scripta Materialia, Vol. 74

Intra granular precipitation and grain boundary segregation under neutron irradiation in a low purity Fe–Cr based alloy

journal, June 2012

- Kuksenko, V.; Pareige, C.; Pareige, P.

- Journal of Nuclear Materials, Vol. 425, Issue 1-3

Cr precipitation in neutron irradiated industrial purity Fe–Cr model alloys

journal, January 2013

- Kuksenko, V.; Pareige, C.; Pareige, P.

- Journal of Nuclear Materials, Vol. 432, Issue 1-3

Atom probe study of irradiation-enhanced α′ precipitation in neutron-irradiated Fe–Cr model alloys

journal, July 2015

- Chen, Wei-Ying; Miao, Yinbin; Wu, Yaqiao

- Journal of Nuclear Materials, Vol. 462

Behaviour of P, Si, Ni impurities and Cr in self ion irradiated Fe–Cr alloys – Comparison to neutron irradiation

journal, January 2015

- Pareige, C.; Kuksenko, V.; Pareige, P.

- Journal of Nuclear Materials, Vol. 456

Works referencing / citing this record:

α′ formation kinetics and radiation induced segregation in neutron irradiated 14YWT nanostructured ferritic alloys

journal, June 2019

- Aydogan, E.; Martinez, E.; March, K.

- Scientific Reports, Vol. 9, Issue 1

Search WorldCat to find libraries that may hold this journal

Search WorldCat to find libraries that may hold this journal