Comparison of heat flux measurement techniques during the DIII-D metal ring campaign

- Sandia National Lab. (SNL-CA), Livermore, CA (United States)

- Oak Ridge National Laboratory (ORNL), Oak Ridge, TN (United States)

- Lawrence Livermore National Lab. (LLNL), Livermore, CA (United States)

- General Atomics, San Diego, CA (United States)

- Univ. of California, San Diego, CA (United States)

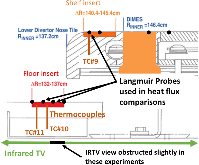

The heat fluxes expected in the ITER divertor raise concerns about the damage tolerances of tungsten, especially due to thermal transients caused by edge localized modes (ELMs) as well as frequent temperature cycling from high to low extremes. Thus we are motivated to understand the heat flux conditions that can cause not only enhanced erosion but also bulk thermo-mechanical damage to a tungsten divertor. For the metal ring campaign in DIII-D, tungsten-coated TZM tile inserts were installed making two toroidal arrays of metal tile inserts in the lower divertor. This study examines the deposited heat flux on these rings with embedded thermocouples (TCs) sampling at 10 kHz and compares them to Langmuir probe (LP) and infrared thermography (IRTV) heat flux measurements. We see agreement of the TC, LP, and IRTV data within 20% of the heat flux averaged over the entire discharge, and that all three diagnostics suggest parallel heat flux at the OSP location increases linearly with input heating power. The TC and LP heat flux time traces during the discharge trend together during large changes to the average heat flux. By subtracting the LP measured inter-ELM heat flux from TC data, using a rectangular ELM energy pulse shape, and taking the relative size and duration of each ELM from $${{D}}_{\alpha }$$ measurements, we extract the ELM heat fluxes from TC data. This over-estimates the IRTV measured ELM heat fluxes by a factor of 1.9, and could be due to the simplicity of the TC heat flux model and the assumed ELM energy pulse shape. ELM heat fluxes deposited on the inserts are used to model tungsten erosion in this campaign. These TC ELM heat flux estimates are used in addition to IRTV, especially in cases where the IRTV view to the metal ring is obstructed. We observe that some metal inserts were deformed due to exposed leading edges. The thermal conditions on these inserts are investigated with the thermal modeling code ABAQUS using our heat flux measurements when these edges were exposed. We report on how the thermal cycling on the ends of the inserts caused this deformation.

- Research Organization:

- Oak Ridge National Lab. (ORNL), Oak Ridge, TN (United States)

- Sponsoring Organization:

- USDOE Office of Science (SC), Fusion Energy Sciences (FES)

- Grant/Contract Number:

- AC05-00OR22725

- OSTI ID:

- 1513373

- Journal Information:

- Physica Scripta, Vol. T170, Issue T170; ISSN 0031-8949

- Publisher:

- IOP PublishingCopyright Statement

- Country of Publication:

- United States

- Language:

- English

Web of Science

Similar Records

Thermal management of tungsten leading edges in DIII-D

The Design and Use of Tungsten Coated TZM Molybdenum Tile Inserts in the DIII-D Tokamak Divertor