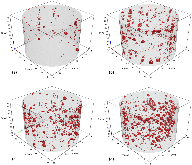

Effect of laser power on defect, texture, and microstructure of a laser powder bed fusion processed 316L stainless steel

Journal Article

·

· Materials & Design

- Univ. of Tennessee, Knoxville, TN (United States)

- Argonne National Lab. (ANL), Argonne, IL (United States)

- Lawrence Livermore National Lab. (LLNL), Livermore, CA (United States)

- CNS/Y-12 National Security Complex, Oak Ridge, TN (United States)

- Research Organization:

- Argonne National Lab. (ANL), Argonne, IL (United States); Oak Ridge Y-12 Plant (Y-12), Oak Ridge, TN (United States); Lawrence Livermore National Lab. (LLNL), Livermore, CA (United States)

- Sponsoring Organization:

- USDOE Office of Science (SC), Basic Energy Sciences (BES). Scientific User Facilities Division; USDOE National Nuclear Security Administration (NNSA)

- Grant/Contract Number:

- AC02-06CH11357; NA0001942; AC52-07NA27344

- OSTI ID:

- 1504438

- Alternate ID(s):

- OSTI ID: 1477038; OSTI ID: 1493501; OSTI ID: 1569670

- Report Number(s):

- IROS6359; IROS7659; LLNL-JRNL-783860; 151384

- Journal Information:

- Materials & Design, Vol. 164; ISSN 0264-1275

- Publisher:

- ElsevierCopyright Statement

- Country of Publication:

- United States

- Language:

- English

Cited by: 129 works

Citation information provided by

Web of Science

Web of Science

Similar Records

Variation of elastic mechanical properties with texture, porosity, and defect characteristics in laser powder bed fusion 316L stainless steel

Effect of laser power on roughness and porosity in laser powder bed fusion of stainless steel 316L alloys measured by X-ray tomography

Gaussian process-based surrogate modeling framework for process planning in laser powder-bed fusion additive manufacturing of 316L stainless steel

Journal Article

·

Mon Jun 17 00:00:00 EDT 2019

· Materials Science and Engineering. A, Structural Materials: Properties, Microstructure and Processing

·

OSTI ID:1504438

+5 more

Effect of laser power on roughness and porosity in laser powder bed fusion of stainless steel 316L alloys measured by X-ray tomography

Journal Article

·

Wed Jan 01 00:00:00 EST 2020

· International Journal of Materials Research

·

OSTI ID:1504438

+3 more

Gaussian process-based surrogate modeling framework for process planning in laser powder-bed fusion additive manufacturing of 316L stainless steel

Journal Article

·

Fri Sep 22 00:00:00 EDT 2017

· International Journal of Advanced Manufacturing Technology

·

OSTI ID:1504438

+2 more