In situ recovery of bio-based carboxylic acids

- National Renewable Energy Lab. (NREL), Golden, CO (United States)

- Pennsylvania State Univ., University Park, PA (United States)

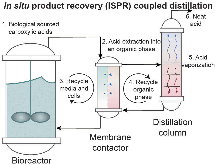

The economics of chemical and biological processes is often dominated by the expense of downstream product separations from dilute product streams. Continuous separation techniques, such as in situ product recovery (ISPR), are attractive in that they can concentrate products from a reactor and minimize solvent loss, thereby increasing purity and sustainability of the process. In bioprocesses, ISPR can have an additional advantage of increasing productivity by alleviating product inhibition on the microorganism. In this work, we developed a liquid–liquid extraction (LLE)-based ISPR system integrated with downstream distillation to selectively purify free carboxylic acids, which were selected as exemplary bioproducts due to their ability to be produced at industrially relevant titers and productivities. Equilibrium constants for the extraction of carboxylic acids into a phosphine-oxide based organic phase were experimentally determined. Complete recovery of acids from the extractant and recyclability of the organic phase were demonstrated through multiple extraction–distillation cycles. Using these data, an equilibrium model was developed to predict the acid loading in the organic phase as a function of the extraction equilibrium constant, initial aqueous acid concentration, pH, organic to aqueous volume ratio, and temperature. A distillation process model was then used to predict the energy input required to distill neat acid from an organic phase as a function of the acid loading in the organic phase feed. The heat integrated distillation train can achieve neat recovery of acetic acid with an energy input of 2.6 MJ kg-1 of acetic acid. This LLE-based ISPR system integrated with downstream distillation has an estimated carbon footprint of less than 0.36 kg CO2 per kg of acetic acid, and provides a green approach to enable both new industrial bioprocesses, and process intensification of existing industrial operations by (1) increasing the productivity and titer of the bioprocess via decreasing end-product inhibition, (2) minimizing downstream separation energy input to less than 20% of the heating value of the product, and (3) generating no waste products.

- Research Organization:

- National Renewable Energy Lab. (NREL), Golden, CO (United States)

- Sponsoring Organization:

- USDOE Office of Energy Efficiency and Renewable Energy (EERE)

- Grant/Contract Number:

- AC36-08GO28308

- OSTI ID:

- 1432608

- Alternate ID(s):

- OSTI ID: 1434342

- Report Number(s):

- NREL/JA-5100-71279; GRCHFJ

- Journal Information:

- Green Chemistry, Vol. 20, Issue 8; ISSN 1463-9262

- Publisher:

- Royal Society of ChemistryCopyright Statement

- Country of Publication:

- United States

- Language:

- English

Web of Science

Ionic liquid-high performance extractive approach to recover carotenoids from Bactris gasipaes fruits

|

journal | January 2019 |

Assessing the stability and techno-economic implications for wet storage of harvested microalgae to manage seasonal variability

|

journal | April 2019 |

Eco-efficient recovery of bio-based volatile C2–6 fatty acids

|

journal | April 2019 |

In situ product recovery of bio-based ethyl esters via hybrid extraction-distillation

|

journal | January 2019 |

Revisiting alkaline aerobic lignin oxidation

|

journal | January 2018 |

Similar Records

Task 2.1: Adsorption-Based ISPR for BETO-Relevant Bioproducts

Increasing the productivity of bioconversion processes