Large moments in bcc FexCoyMnz ternary alloy thin films

- Montana State Univ., Bozeman, MT (United States)

- Lawrence Berkeley National Lab. (LBNL), Berkeley, CA (United States)

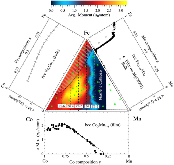

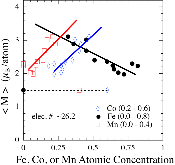

The elemental magnetic moments and the average atomic moment of 10-20 nm thick single crystal bcc (bct) FexCoyMnz films deposited on MgO(001) have been determined as a function of a broad range of compositions. Thin film epitaxy stabilized the bcc structure for 80% of the available ternary compositional space compared to only a 23% stability region for the bulk. The films that display ferromagnetism represent 60% of the available compositional possibilities compared to 25% for the bulk. A maximum average atomic moment of 3.25 ± 0.3 μB/atom was observed for a bcc Fe9Co62Mn29 film (well above the limit of the Slater-Pauling binary alloy curve of 2.45 μB/atom). Furthermore, the FexCoyMnz ternary alloys that exhibit high moments can only be synthesized as ultrathin films since the bcc structure is not stable in the bulk for those compositions.

- Research Organization:

- Lawrence Berkeley National Lab. (LBNL), Berkeley, CA (United States)

- Sponsoring Organization:

- USDOE Office of Science (SC)

- Grant/Contract Number:

- AC02-05CH11231

- OSTI ID:

- 1530335

- Alternate ID(s):

- OSTI ID: 1420355

- Journal Information:

- Applied Physics Letters, Vol. 112, Issue 7; ISSN 0003-6951

- Publisher:

- American Institute of Physics (AIP)Copyright Statement

- Country of Publication:

- United States

- Language:

- English

Web of Science

Similar Records

Study of Electronic Structure, Magnetism, and Half-Metallicity of New Heusler Compounds CsTmO{sub 2} (Tm = Fe, Co, Ni, and Cu)

Computational investigation of half-Heusler compounds for spintronics applications